While both regulate flow, a butterfly valve provides a full shut-off capability, while dampers focus on airflow adjustment and isolation within larger ducts and systems.

Damper Valves

Optimize airflow control for industrial efficiency

We are leading Damper Valve manufacturer in Mumbai India. It is a device used to regulate, control, or isolate airflow and gases in industrial systems, ensuring efficient management of gas and air movement. They are integral to HVAC, exhaust, and processing systems, providing precise flow control essential for system stability and performance.

Damper Valve Types

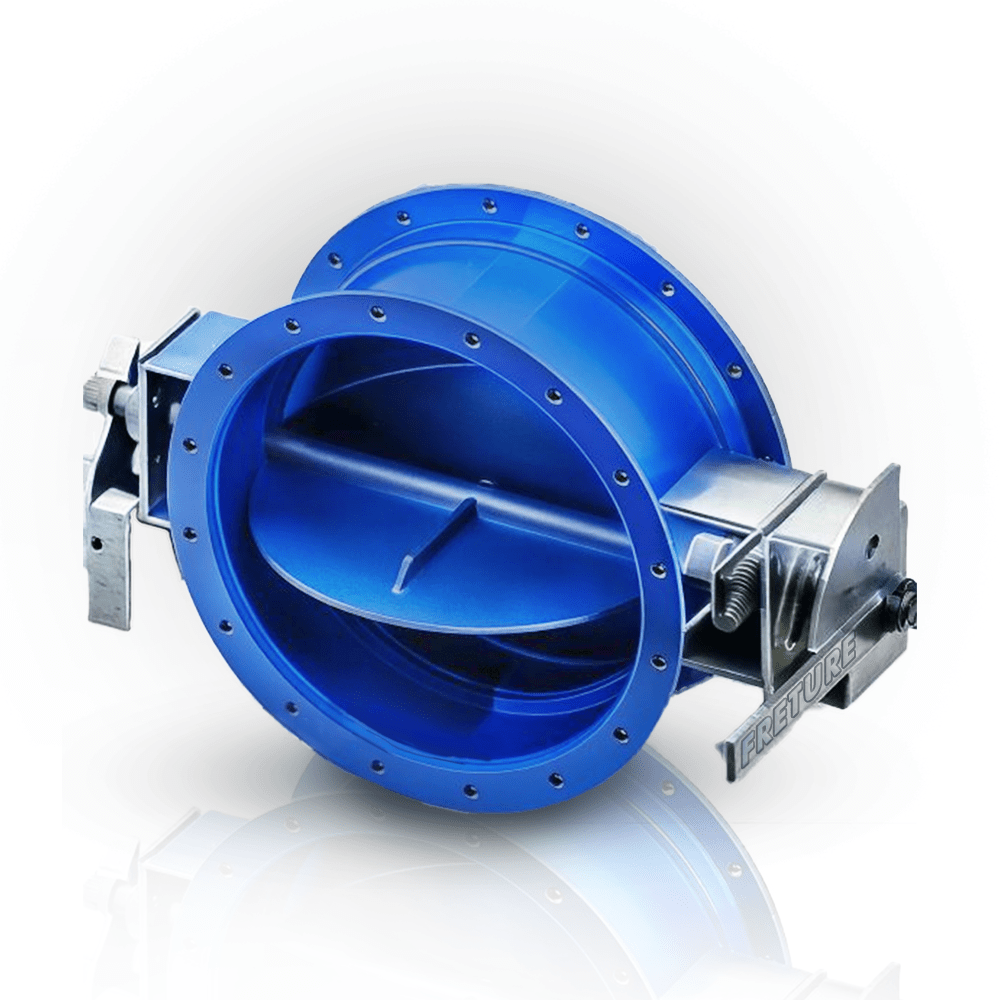

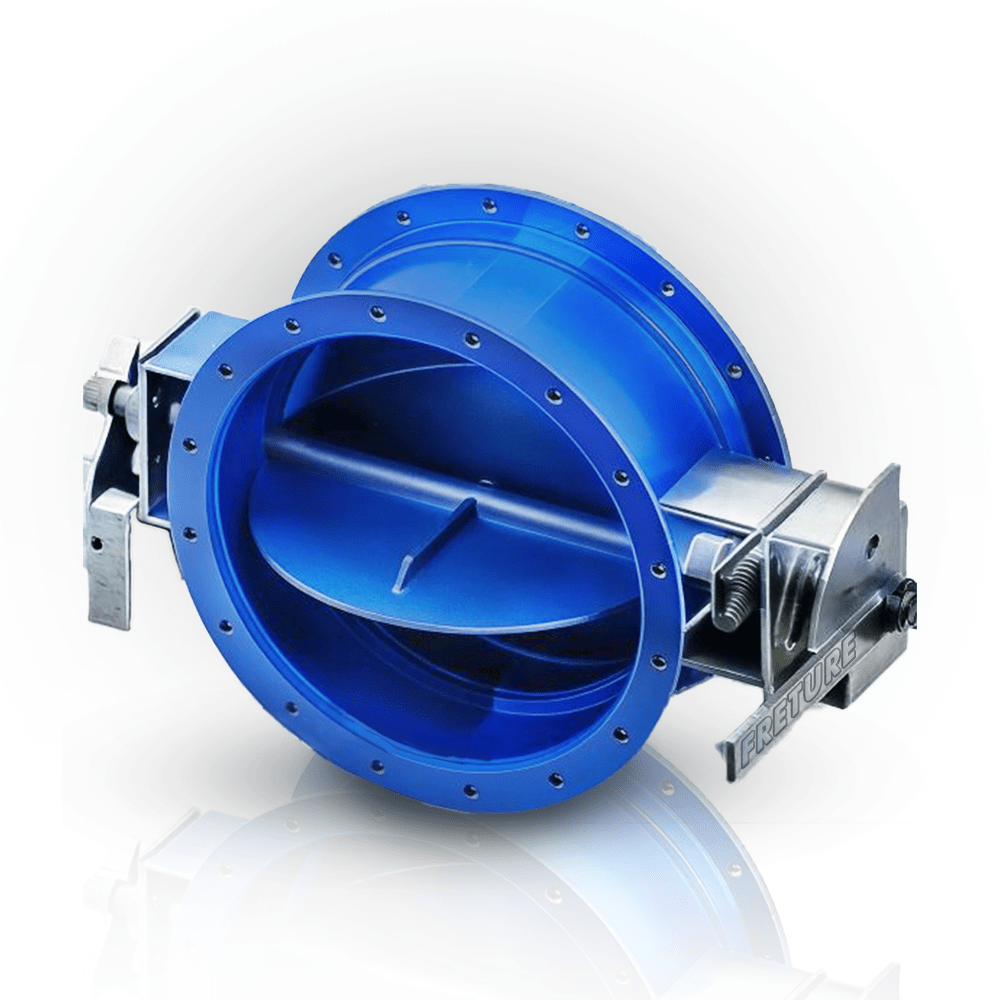

Butterfly Dampers: These dampers use a rotating disc to manage airflow and are known for their compact design and efficient control in HVAC and ventilation systems.

Guillotine Dampers: Designed for complete shut-off, these dampers offer strong isolation in applications like exhaust systems, ensuring minimal leakage and robust flow control.

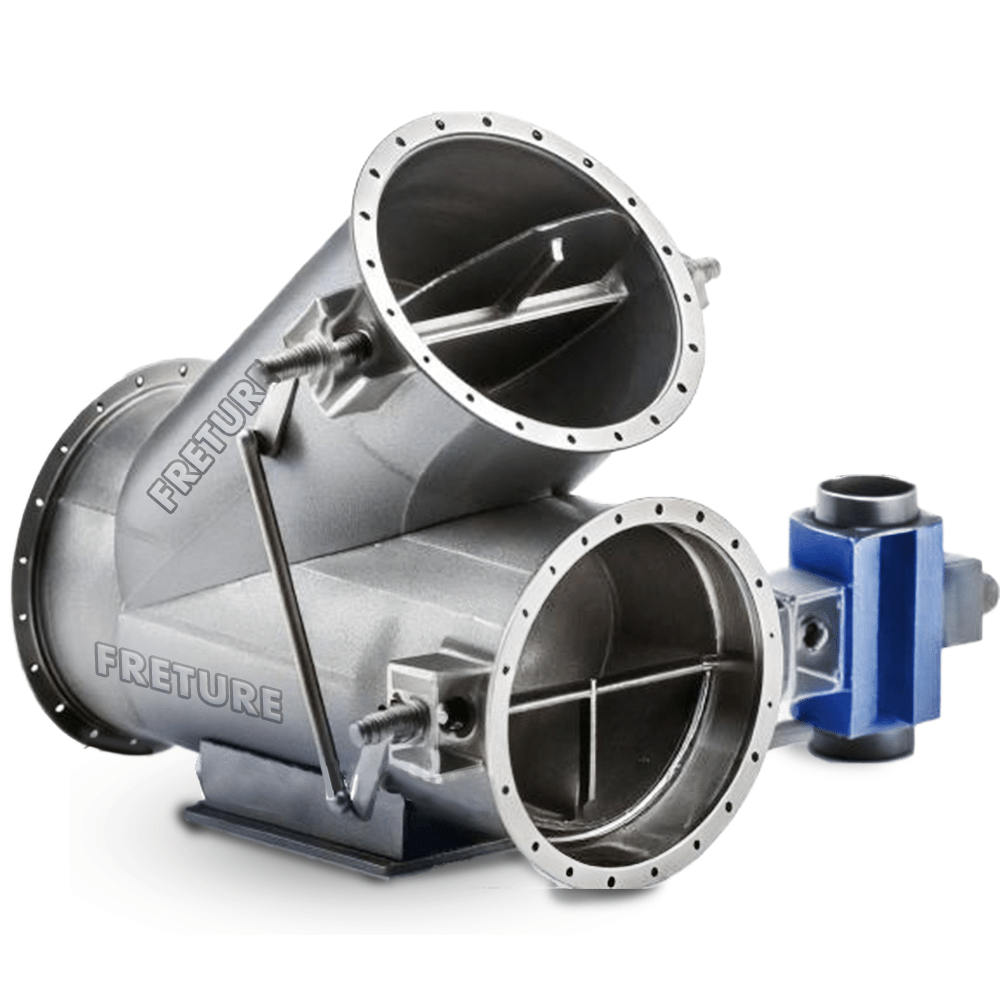

Diverter Dampers: These dampers redirect gas flow between outlets, often in high-temperature applications like gas turbines, and come in louver, flap, and tee styles.

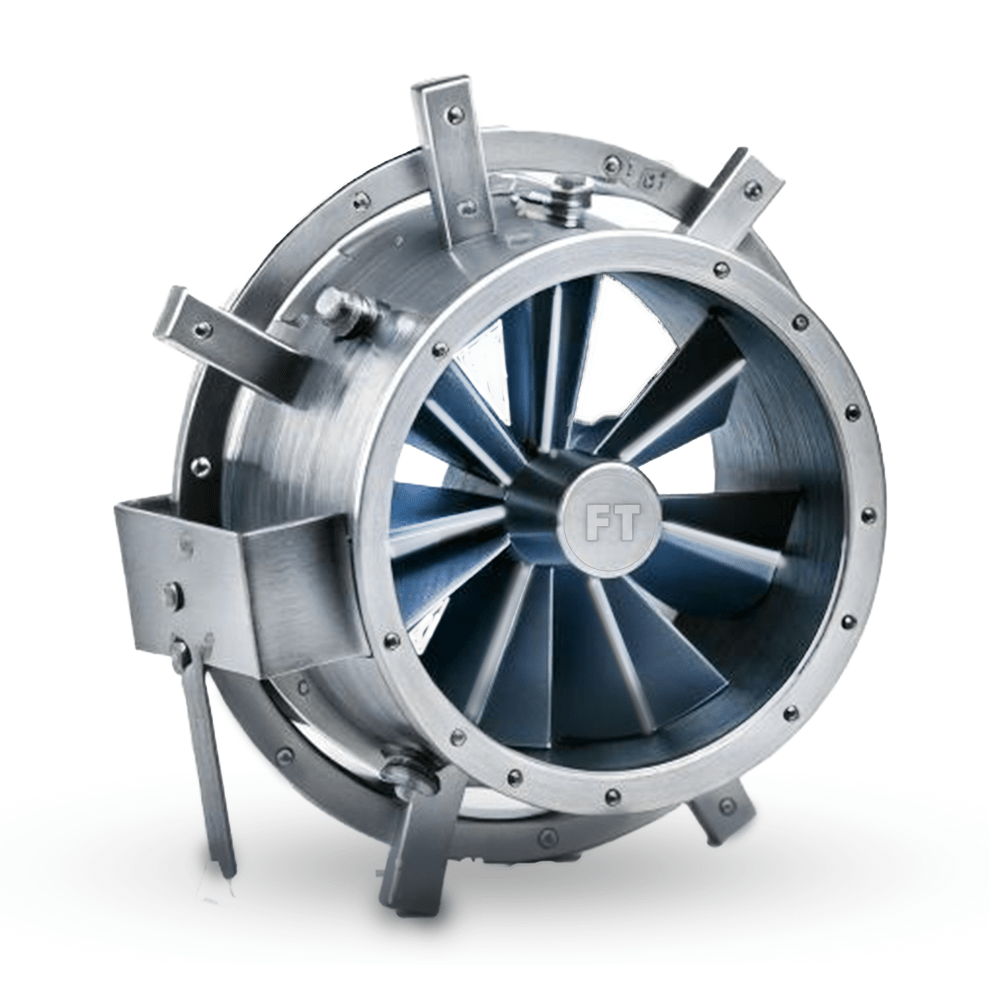

Inlet Vane Dampers: Used for volume control in fans and blowers, these dampers improve energy efficiency by managing air intake as needed. Backdraft Dampers: Prevent reverse airflow in HVAC systems, helping maintain consistent airflow direction for optimized indoor air quality.

Application

These valves typically feature adjustable blades or discs to control the flow, with options for manual, motorized, or pneumatic operation. They are designed for durability, corrosion resistance, and minimal leakage, with materials chosen for specific environments, such as stainless steel for corrosive applications.

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is the difference between a damper valve and a butterfly valve?

- What is the purpose of dampers?

Dampers control and manage airflow and gas direction, improve system efficiency, and provide safety by isolating sections in ventilation and exhaust systems.

- What are the three main types of dampers?

The main types are Butterfly, Guillotine, and Diverter Dampers; each serves specific needs in airflow control, isolation, and direction adjustment. These valves ensure reliable performance across industrial applications, offering tailored solutions for efficient and safe system management.

- What is a damper valve, and how does it work?

A damper valve is a device that regulates or controls airflow or gas flow in industrial systems. It typically operates by adjusting a blade or set of blades to control the flow rate, either partially or fully, depending on system requirements.

- What are the main types of these valves?

The primary types include Butterfly Dampers (for efficient control in ventilation), Guillotine Dampers (for complete shut-off), Diverter Dampers (for redirecting flow), Refractory Dampers (for high-temperature resistance), Inlet Vane Dampers (for fan volume control), and Backdraft Dampers (to prevent reverse flow).

- What materials are used in these valve construction?

They are made from various materials depending on application needs, such as stainless steel, carbon steel, and refractory-lined materials for high-temperature resistance. Material selection helps ensure durability and resistance to corrosion or wear.

- Where are these valves typically used?

They are commonly used in HVAC systems, power plants, boilers, exhaust systems, cogeneration, heat recovery units, and industrial gas processing to control, regulate, or isolate airflow or gases.

- How do motorized and manual these valves differ?

Motorized dampers are controlled electrically or pneumatically, providing automated operation for more precise control, while manual dampers are manually adjusted and are typically used in applications where frequent adjustments are not required.

- What is the purpose of a backdraft damper?

Backdraft dampers prevent reverse airflow, ensuring that air flows in one direction only. They are particularly useful in HVAC systems and ventilation systems to maintain air quality and system efficiency.

- Are these valves suitable for high-temperature applications?

Yes, certain these valves, such as refractory dampers, are specifically designed for high-temperature environments. These valves are lined with materials that withstand extreme heat, making them suitable for applications in power plants, incineration, and combustion systems.

- How do I select the right damper valve for my application?

Selection depends on factors like the operating temperature, pressure, type of gas or air being controlled, flow control requirements, and whether automated or manual operation is needed. Consulting with a manufacturer or supplier can help ensure the right choice.

- What maintenance is required for these valves?

These valves generally require periodic inspection and cleaning to ensure proper function. Maintenance may include checking for wear or corrosion, lubricating moving parts, and testing for consistent performance, especially in high-demand applications.

Industries where Damper Valves is used

Power Generation

Petrochemical Industry

Pulp and Paper Industry

HVAC System

Pharmaceutical Industry

Applications

- Industrial Ventilation: Controls airflow in HVAC and exhaust systems.

- Power Generation: Manages high-temperature gases in turbines and exhausts.

- Manufacturing: Provides flow isolation and direction control in processing plants.

- HVAC: Ensures controlled airflow, energy efficiency, and prevents backflow.