The PTFE lining acts as a protective barrier, preventing corrosion and erosion caused by aggressive chemicals, thereby enhancing durability and reducing maintenance.

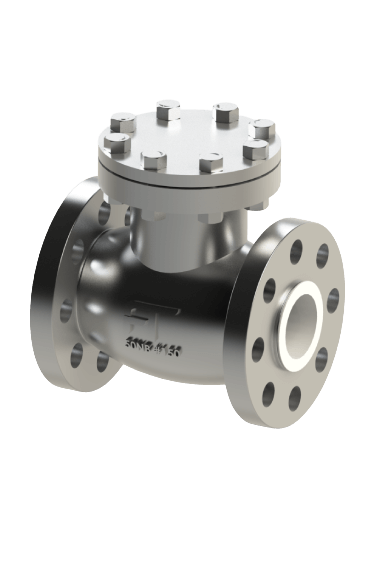

PFA / PTFE LINED SWING CHECK VALVE

One-way flow, guaranteed.

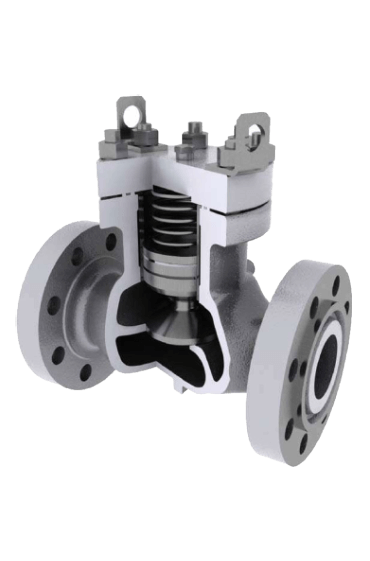

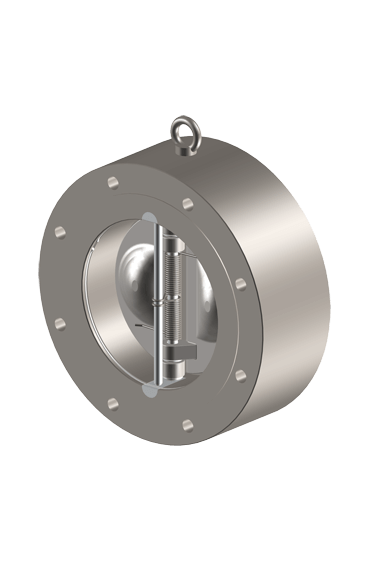

Freture Techno is leading PFA / PTFE lined swing check valve manufacturers in Mumbai, India. These check valve also known as a lined wafer check valve is an important part of industrial piping systems, designed to allow unidirectional fluid flow and prevent backflow. It operates using a wafer disc that swings open with forward flow and closes when the flow reverses, ensuring that the medium flows in only one direction. The interior surfaces of these valves are lined with corrosion-resistant materials such as polytetrafluoroethylene (PTFE), perfluoroalkoxy alkane (PFA), or fluorinated ethylene propylene (FEP). This lining provides exceptional chemical resistance, making a swing lined check valve ideal for handling highly corrosive substances in industries like chemical processing, pharmaceuticals, and petrochemicals.

The construction of these lined swing check valves typically involves a robust body made from materials like ductile iron or carbon steel, which is then lined with PTFE, PFA, or FEP to protect against corrosive media. The disc, often fully encapsulated in the lining material, swings on a hinge to open or close the valve. Some designs feature an anti-blowout stem assembly to prevent stem blowout even when the top gear is disassembled, enhancing operational safety. Additionally, these valves are designed with short pattern face-to-face dimensions in accordance with ANSI standards, facilitating easy replacement of existing valves without altering the existing pipework.

Incorporating the swing check valve into your piping systems offers several benefits, including enhanced durability, improved safety, and environmental sustainability. The corrosion-resistant lining reduces maintenance frequency and prevents leaks, ensuring a safer working environment and minimizing environmental contamination. Moreover, the these swing check valve extends the lifespan of these valves and contributes to sustainable industrial practices by reducing the need for frequent replacements and lowering material consumption. By maintaining reliable, leak-free performance,These check valves support efficient and eco-friendly operations across various industries.

Specifications | Features |

|---|---|

Type: Lined Swing Check Valve End Connection: Flanged, Threaded, Socket Weld, Butt Weld (ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1) Size: 50NB - 600NB Pressure Rating: 150# - 2500# Temperature: -29°C to 425°C (-20°F to 800°F) Material: Cast Iron, Stainless Steel, Carbon Steel, Alloy Steel, etc. Design Standard: API 594, API 6D, ASME B16.34 Leakage Class: ANSI Class VI (Zero Leakage) Seat: Nitrile, EPDM, or Viton (metal-to-Metal, soft-seated) Safety: BS/EN, NACE, API 598 Rev 2009, API 607 Rev 2010 | Swing Disc Mechanism: Utilizes a hinged disc that swings open and close Efficiently. Low Pressure Drop: Minimizes pressure loss for efficient fluid flow. Unidirectional Flow: Allows flow in one direction while preventing backflow. Automatic Operation: Functions without the need for external control. Low Friction Operation: Minimizes friction for efficient flow. Pressure Rating: Capable of withstanding high-pressure environments. Long Service Life: Durable construction ensures a long operational lifespan. Corrosion Resistance: Offers excellent resistance to harsh environments. |

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How does the PTFE lining improve valve performance?

- What industries are PTFE Lined Valve suitable for?

Ideally suited for industries dealing with corrosive or abrasive media, such as pharmaceuticals, chemicals, water treatment, food processing, and slurry systems.

- Can these Lined Check valves handle high-temperature applications?

Yes, PTFE-lined valves can withstand moderate to high temperatures depending on the lining material (PTFE, PFA, or FEP) and process requirements.

- How do these Lined Check valves compare to high-alloy valves in terms of cost?

PTFE-lined valves offer a cost-effective alternative to high-alloy valves, providing excellent corrosion resistance at a significantly lower investment.

- Can these valves handle slurry or solids-laden fluids?

Yes, the smooth internal surface of the PTFE lining and swing mechanism allows them to handle slurry and solids-laden fluids effectively.

- Do these valves require regular maintenance?

No, the valves have minimal moving parts and are highly resistant to wear, reducing the need for frequent maintenance.

- What size is available for PTFE Lined Swing Check Valve?

Freture offers these valves in a wide range of sizes, from 1” NB to 12” NB, catering to diverse flow requirements.

Oil and Gas Industry

Water Treatment

Chemical Processing

HVAC Systems

Power Generation

Applications

- Acid Production: Safely handling and preventing backflow of strong acids like sulfuric and hydrochloric acid.

- Solvent Extraction: Managing the flow of organic solvents used in chemical separations.

- Aromatic Compound Production: Handling corrosive substances in the production of benzene, toluene, and xylene.

- Polyethylene and Polypropylene Manufacturing: Controlling monomer flow in polymerization reactors.

- Drug Refining: Handling corrosive syrups and preventing crystallization blockages.