PTFE, PFA, and FEP Ball Valves are types of valves designed for handling corrosive and high-purity fluids in various industries. They are made from materials such as polytetrafluoroethylene (PTFE), perfluoroalkoxy (PFA), and fluorinated ethylene propylene (FEP), offering exceptional chemical resistance and purity. These valves are used in applications where standard metal valves may risk corrosion or contamination.

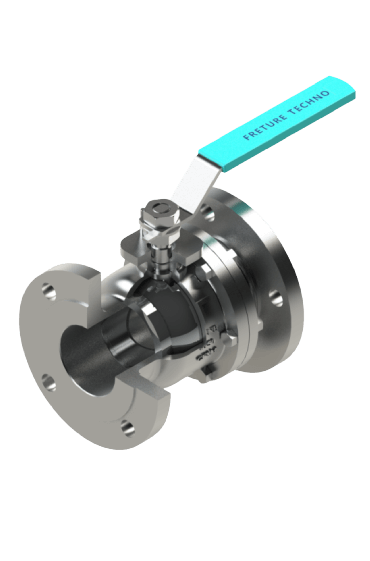

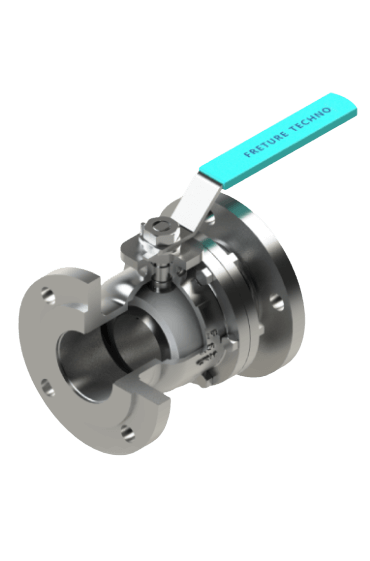

PTFE Lined Ball Valve

We are a leading PFA, FEP, PVDF, PTFE Lined Ball Valve Manufacturer in Mumbai, India. In the world of industrial valves, the choice of the right valve is crucial for ensuring efficient and reliable operations. One such valve that plays a vital role in various industries is the lined ball valve. These valves are widely used for their durability, versatility, and ability to handle corrosive and abrasive fluids. When it comes to selecting a manufacturer for lined ball valves, Freture Techno stands out as a top choice. In this article, we will delve into the world of lined ball valves and explore why Freture Techno is the preferred supplier for these critical components.

Understanding PFA, FEP, PVDF, PTFE Lined Ball Valve

They are essential components in industries such as chemical processing, pharmaceuticals, petrochemicals, and more. These valves are designed to handle corrosive and aggressive fluids, which are common in many industrial processes. The key feature of a PTFE Lined Ball Valve is its corrosion-resistant lining, typically made from materials like PTFE (Polytetrafluoroethylene) or PFA (Perfluoroalkoxy). This lining protects the valve's internals from the harsh chemicals and ensures a longer service life.

Why Choose Freture Techno?

- Expertise and Experience: Freture Techno has a rich history in manufacturing industrial valves, including Lined Ball Balves. With decades of experience, they have honed their expertise in producing high-quality valves that meet industry standards.

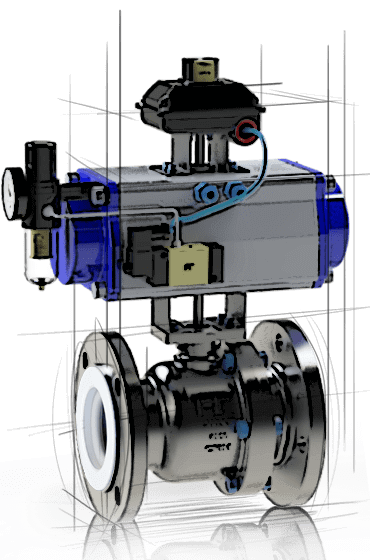

- Customization: Freture Techno understands that every application is unique. They offer a wide range of customizable options for Lined Ball Valves, including materials, sizes, and end connections. This flexibility ensures that you get the perfect valve for your specific needs.

- Quality Assurance: Freture Techno places a strong emphasis on quality control and assurance. Freture valves undergo rigorous testing to ensure they meet the highest standards for performance, reliability, and safety. This commitment to quality gives customers peace of mind in their valve selection.

- Corrosion Resistance: Freture Techno's provides high-quality PTFE and PFA linings, providing excellent resistance to corrosive fluids. This durability ensures a longer service life and minimizes maintenance costs.

- Technical Support: Choosing the right valve can be a complex process. Freture Techno offers excellent technical support and guidance to help you select the most suitable PTFE, PFA, FEP Lined Ball Valve for your application.

- Competitive Pricing: While Freture Techno delivers top-notch quality, we also offer competitive pricing. This combination of quality and affordability makes them an attractive choice for many industries.

- Global Reach: Freture Techno has a global presence, ensuring that their high-quality lined ball valves are accessible to customers worldwide. Our distribution network and customer support extend to various regions, making it convenient for customers to procure our valves.,PFA, FEP, PVDF, PTFE Lined Ball Valve plays a vital role in ensuring the safe and efficient handling of corrosive fluids. When selecting a supplier for these critical components, Freture Techno emerges as a top choice due to their extensive experience, commitment to quality, customization options, and competitive pricing. Whether you operate in the chemical, pharmaceutical, or petrochemical industry, Freture Techno's lined PFA, FEP, PVDF, PTFE Ball valves are a reliable and cost-effective solution that can enhance your operations and provide long-lasting performance. Choose Freture Techno for your lined ball valve needs, and experience the difference in quality and service that sets them apart from the competition.

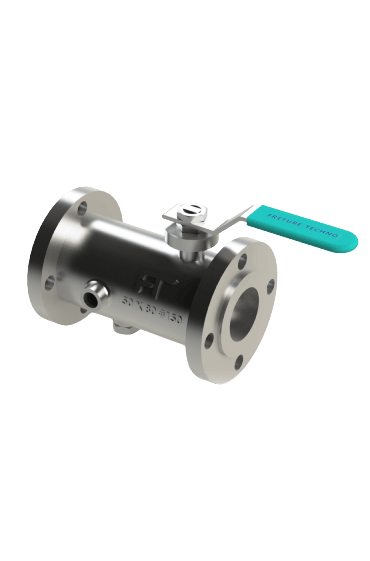

Specifications | Features |

|---|---|

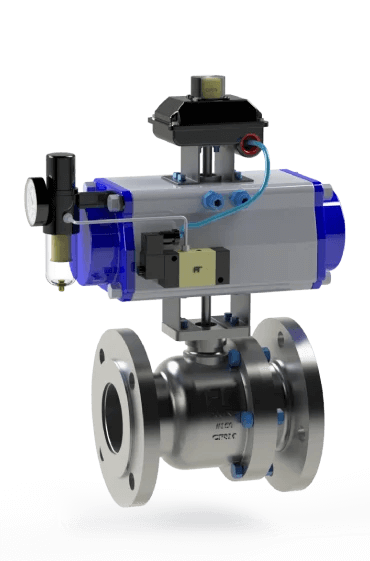

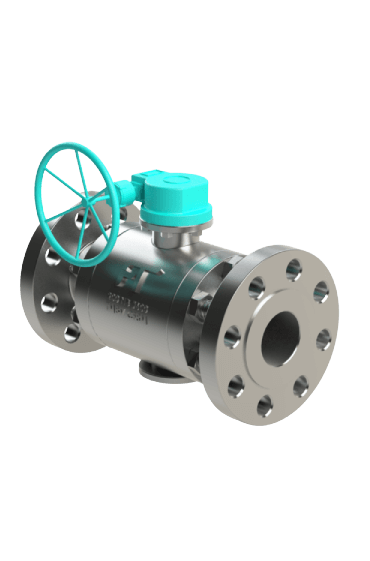

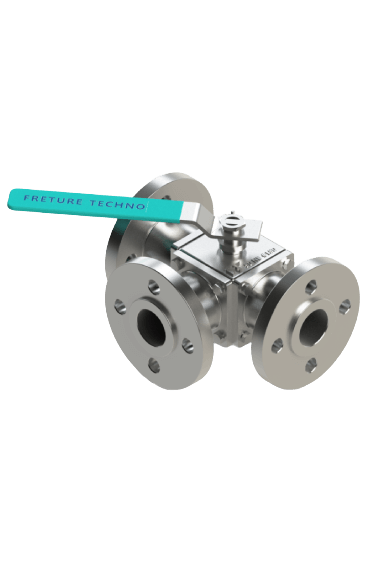

Type: Floating/ Trunnion (one / two / Three (L/T Port) End Connection: Flanged ( ASME B16.5 ) Size: 15 NB - 300NB Pressure Rating Class: 150# - 2500# Temperature Range: 7°C to 280°C Body Material: Carbon Steel, Stainless Steel, Ductile Iron Design Standard: API 6D / ISO 17292 / ASME B16.34 / API 607 Lining Material: PTFE, PFA, FEP, PVDF, Polypropylene, or other suitable materials Face to Face: ANSI B16.10 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is PTFE, PFA, and FEP Ball Valves?

- How does it work?

PTFE, PFA, and FEP Ball Valves operate similarly to standard ball valves, using a spherical ball with a hole through the middle to control fluid flow. When the valve is open, the hole in the ball aligns with the flow path, allowing fluid to pass through. When closed, the ball rotates to block the flow.

- What are the main applications?

PTFE, PFA, and FEP Ball Valves are commonly used in industries such as chemical processing, pharmaceuticals, food and beverage, semiconductor manufacturing, and water treatment for corrosive and high-purity fluid handling applications.

- What are the benefits of using one?

The benefits of using PTFE, PFA, and FEP Ball Valves include excellent chemical resistance, high purity, low friction, wide temperature range, and minimal risk of contamination, making them ideal for critical fluid handling applications.

- What materials are used in their construction?

PTFE, PFA, and FEP Ball Valves are constructed using materials such as polytetrafluoroethylene (PTFE), perfluoroalkoxy (PFA), and fluorinated ethylene propylene (FEP), which offer exceptional chemical resistance and purity.

- How do I choose the right one for my application?

When selecting a PTFE, PFA, or FEP Ball Valve, consider factors such as the type of fluid, temperature range, pressure rating, valve size, end connections, and compatibility with the specific application requirements to ensure optimal performance.

- Can they be repaired?

Yes, PTFE, PFA, and FEP Ball Valves can be repaired. Common repairs may include replacing worn seals or damaged components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance of PTFE, PFA, and FEP Ball Valves typically includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage.

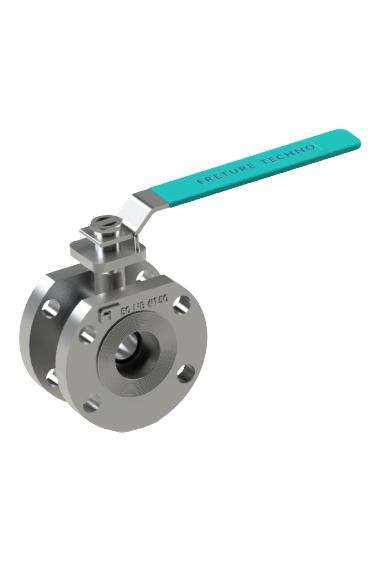

- Are they available in different designs?

Yes, PTFE, PFA, and FEP Ball Valves are available in various designs, including two-way, three-way, and multi-port configurations, as well as different end connections and actuation options to suit different application requirements.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing PTFE, PFA, and FEP Ball Valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. We offer a wide range of high-quality valves, expert technical support, and competitive pricing, ensuring that our customers receive reliable solutions tailored to their needs.

Industries where PTFE Lined Ball Valve is Used

Chemical Processing

Pharmacuticals

Petrochemical Industry

Oil and Gas Industry

Pulp and Paper Industry

Application of PTFE Lined Ball Valve

- Chemical Processing: Handling corrosive chemicals.

- Pharmaceuticals: Managing high-purity fluids.

- Food and Beverage: Ensuring sanitary fluid handling.

- Semiconductor Manufacturing: Controlling ultra-pure chemicals.

- Water Treatment: Managing corrosive and high-purity fluids.

- Aerospace: Handling fluids in critical applications.