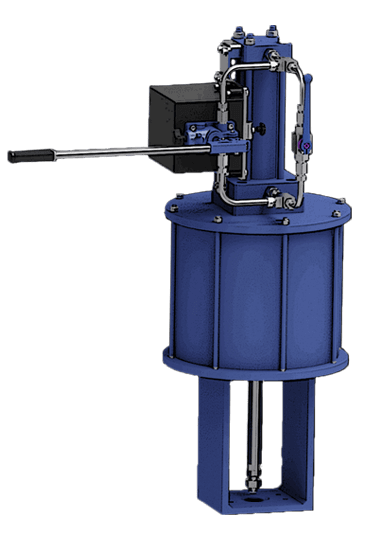

It is a mechanical device used to convert rotary motion into linear motion. It consists of a gear (the pinion) that engages with a linear toothed bar (the rack), allowing for precise and controlled linear movement.

Rack & Pinion Actuator

They are durable, less expensive and are suited best for hazardous environments.

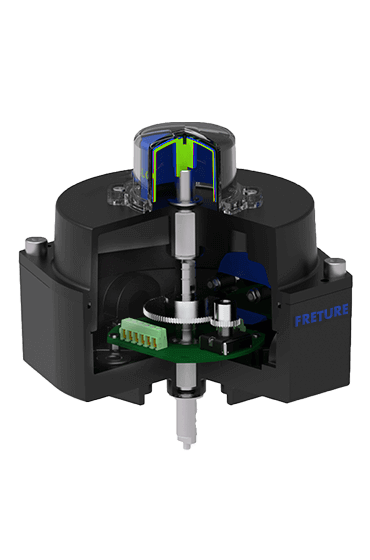

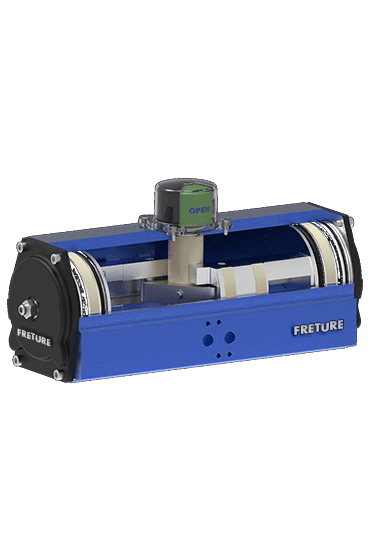

Freture Techno is a premier Pneumatic Rack & Pinion Actuator manufacturer in Mumbai. We specialize in delivering high-quality, robust actuators designed to provide precise linear motion for various industrial applications. The Actuator converts linear motion into rotational motion, providing precise control for various applications. It's known for its reliability and efficiency in automation systems. A Rack & Pinion actuator is a rotary actuator that converts linear motion into rotational motion.

They will serve your need to turn, open, close, mix, oscillate, position, steer and a lot more mechanical function that involves restricted rotation. These can be used for the automation of quarter-turn valves, just like butterfly valves or balls.

Why Choose Freture Techno?

Freture Techno stands out for its commitment to innovation, quality, and customer satisfaction. The actuators are crafted using advanced technology to guarantee superior performance and longevity. We offer customized solutions tailored to meet your specific needs and provide comprehensive support to ensure seamless implementation and operation. Trust Freture Techno for all your Rack & Pinion Actuator requirements and experience enhanced efficiency and reliability in your operations.

Contact us today to learn more about our rack & pinion actuators and how they can enhance your industrial applications.

Description | Features |

|---|---|

TYPE: Rack and pinion, Diaphragm Actuator, vane, helical, etc. Torque: 5 Nm to 5,000,00 Speed: 5°sec - 280°sec Rotation: 0° to 180°(Bidirectional) Air Supply Ports : VDI/VDE3845 NAMUR, EN ISO228 G1/8”, G1/4”, G1/2” Port Size : 1/8 inch to 2 inches (NPT or BSP) Pressure: - 1 bar to 12 bar (14.5 psi to 174 psi) Temperature : Extended Temperature - 60°C to 200°C (-76°F to 392°F) Material: Aluminium, stainless steel, cast iron, carbon steel, etc. Valve Interface: ATEX 2014/34/EU, ISO 5211, DIN 3337,VDE/VDI 3845 (NAMUR) Mounting Options.: flange, foot-mounted, shaft-mounted, etc. Noise Level : 50 dB to 65 dB Cycle Time: 0.1 seconds to 10 seconds Coating Options: PTFE coating,Hard Anodised, Nickel plated Springs:Cartridge: cartridge type,Shot peened. Endurance Testing : 500,000 cycles(EN 15714-3) Compliance : ISO 5211, CE, ATEX, ISO,EN etc. |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Rack & Pinion Actuator?

- How does it work?

They work by utilizing the rotational motion of the pinion gear to drive the linear movement of the rack. As the pinion rotates, it engages with the teeth of the rack, causing it to move linearly along its axis.

- What are the main applications?

They find widespread applications in various industries, including valve automation, conveyor systems, robotics, and automotive manufacturing. They are particularly suitable for applications requiring linear motion control and positioning.

- What are the benefits of using one?

The benefits of using these actuator include precise linear motion control, high-speed operation, compact design, reliability, and suitability for heavy-duty applications. They offer efficient and accurate movement, enhancing productivity and system performance.

- What materials are used in their construction?

They are commonly constructed from materials such as stainless steel, aluminum, and high-strength alloys. The choice of materials depends on factors such as durability, corrosion resistance, and the specific requirements of the application.

- How do I choose the right one for my application?

Choosing the right Rack & Pinion Actuator involves considering factors such as load capacity, stroke length, speed requirements, operating environment, and compatibility with the application's control system. Consulting with a knowledgeable supplier can help in selecting the most suitable actuator for your specific needs.

- Can they be repaired?

Yes, It can often be repaired. Maintenance and repair may involve replacing worn components, lubricating moving parts, and ensuring proper alignment. However, the repairability depends on the extent of damage and the availability of replacement parts.

- What maintenance is required?

Maintenance of these Actuators typically includes regular inspections, lubrication of gears and bearings, checking for wear and tear, and ensuring proper alignment. Following a preventive maintenance schedule can help prolong the actuator's lifespan and maintain optimal performance.

- Are they available in different designs?

Yes, They are available in various designs to suit different application requirements. These designs may include single-acting, double-acting, pneumatic, hydraulic, and electric actuators, each offering specific features and capabilities.

- Why is Freture the best place to buy from?

Freture is the best place to buy Rack & Pinion Actuators due to its extensive range of high-quality products, expert technical support, competitive pricing, and commitment to customer satisfaction. Freture's actuators are designed to meet the highest industry standards, ensuring reliable performance, durability, and compatibility with diverse industrial applications.

Industries where Rack & Pinion Actuator is used

Oil and Gas

Chemical Processing

Water Treatment

Power Generation

Pulp and Paper Industry

Applications of Rack & Pinion Actuators

Valve Automation: They are extensively used for automating valve operations in various industrial settings, ensuring precise control over fluid flow.

Process Control: They play a critical role in process control systems, allowing for accurate adjustment of valve positions to regulate pressure, flow rates, and other process parameters.

Safety Systems: They are integrated into safety systems to quickly and reliably close or open valves in emergency shutdown situations, preventing accidents and ensuring personnel safety.

High-Cycle Applications: They are ideal for high-cycle applications due to their robust design and reliable performance, making them suitable for continuous and demanding industrial processes.

Diverse Industries: They find applications in a wide range of industries, including oil and gas, chemical processing, water treatment, power generation, and pharmaceuticals, due to their versatility and efficiency.