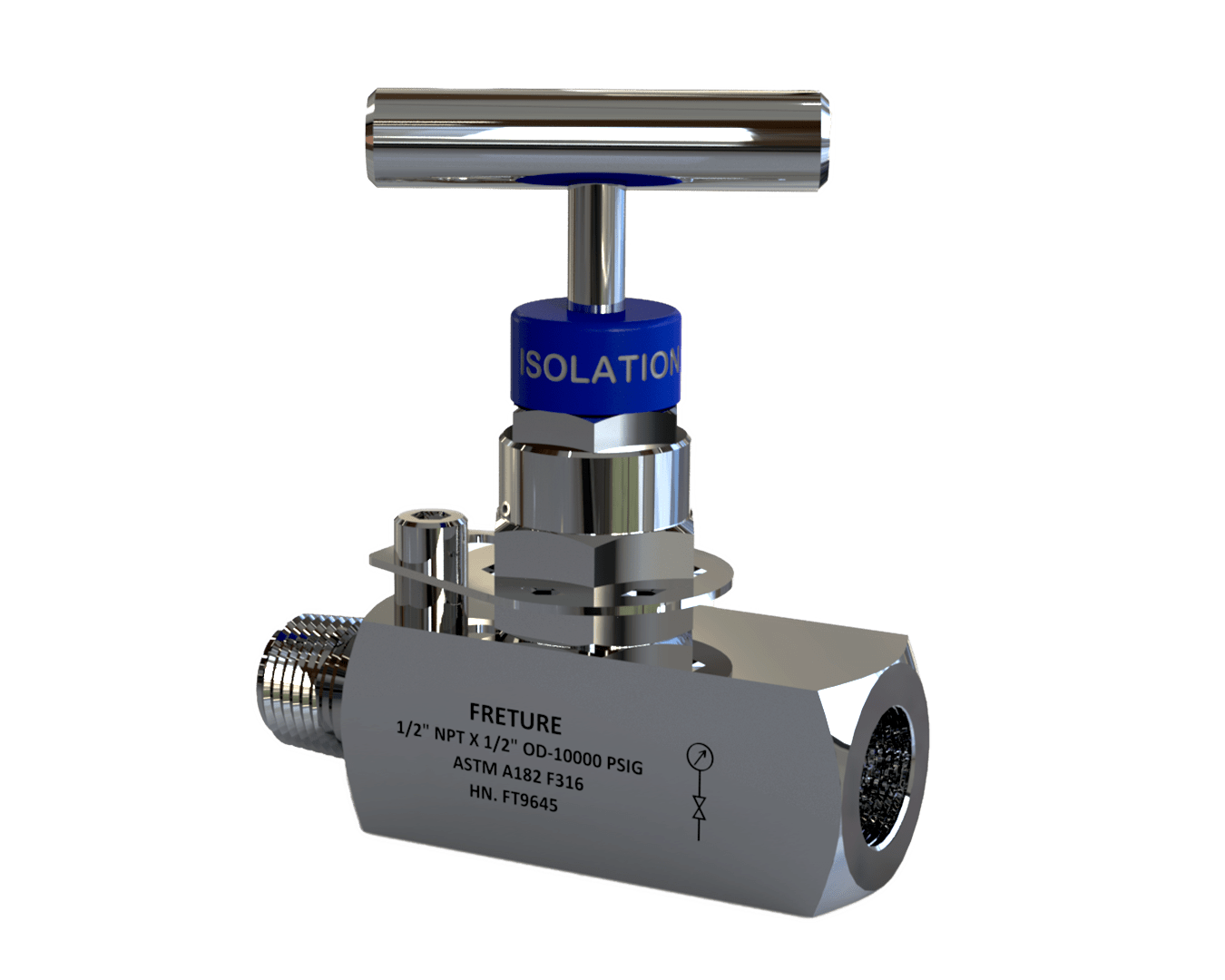

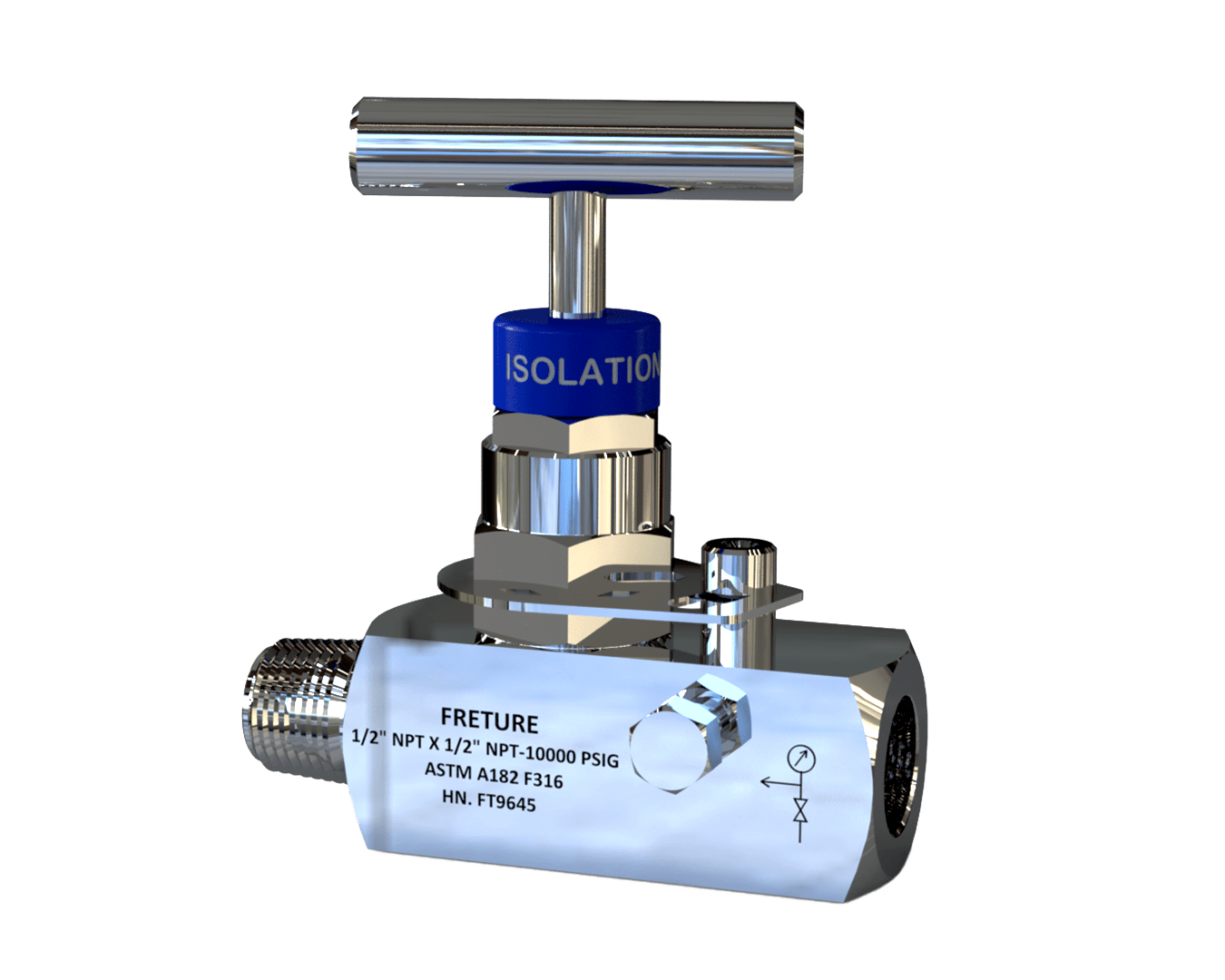

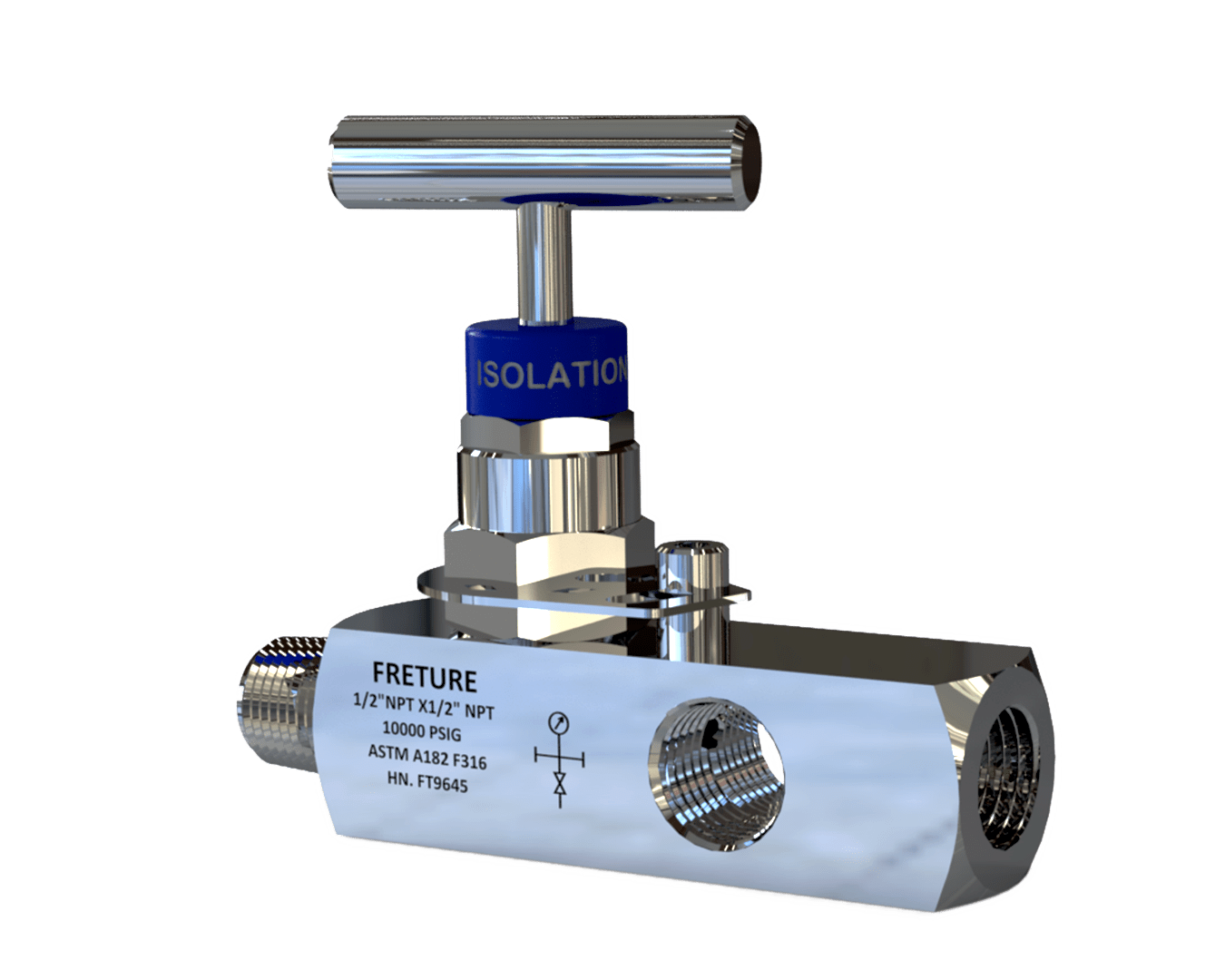

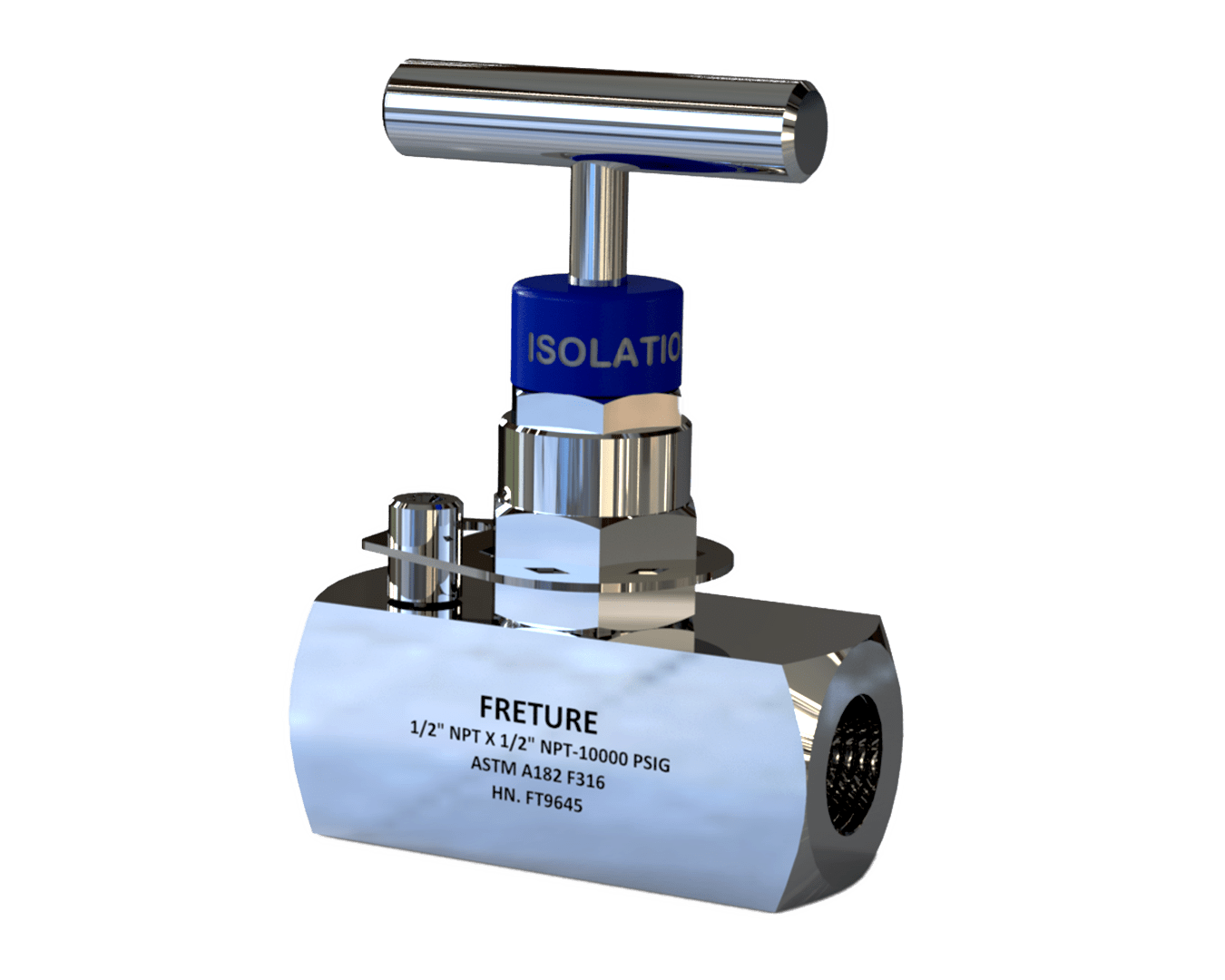

A Needle valve is a type of valve characterized by its slender, tapered point at the end of a valve stem. This design allows for precise flow modulation, making needle valves ideal for applications where fine adjustments are crucial.

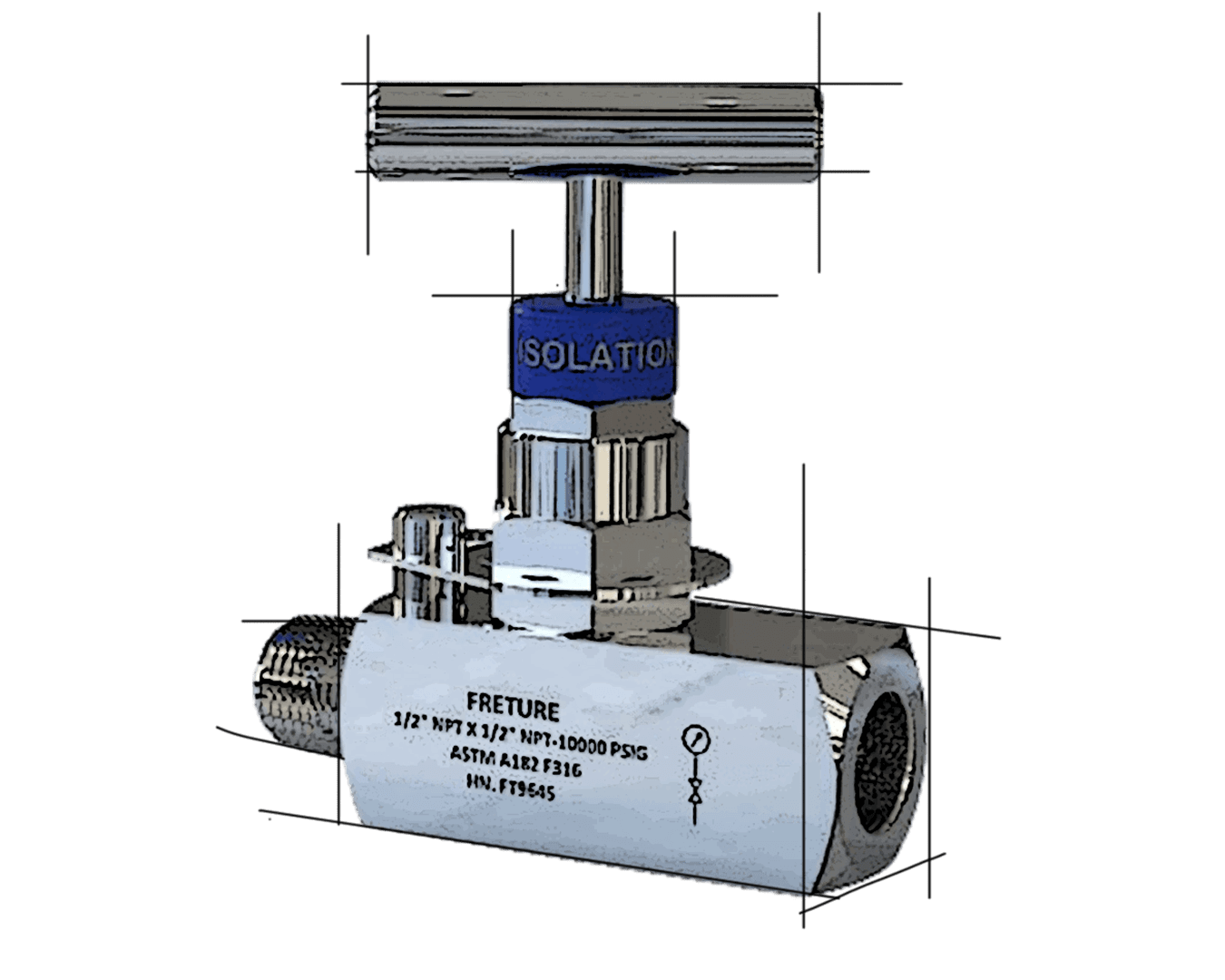

Needle Valve

Needle Valves, linear motion valves, are used to regulate the isolation of the fluid.

We are a leading High Pressure Needle Valve manufacturer in Mumbai, India, committed to delivering high-quality Needle valves (15000 PSI) for various industrial applications. Needle valves play a crucial role in industrial applications by providing precise control over fluid flow. They are essential in systems requiring accurate flow regulation and tight shut-off, ensuring optimal performance and safety in critical processes.

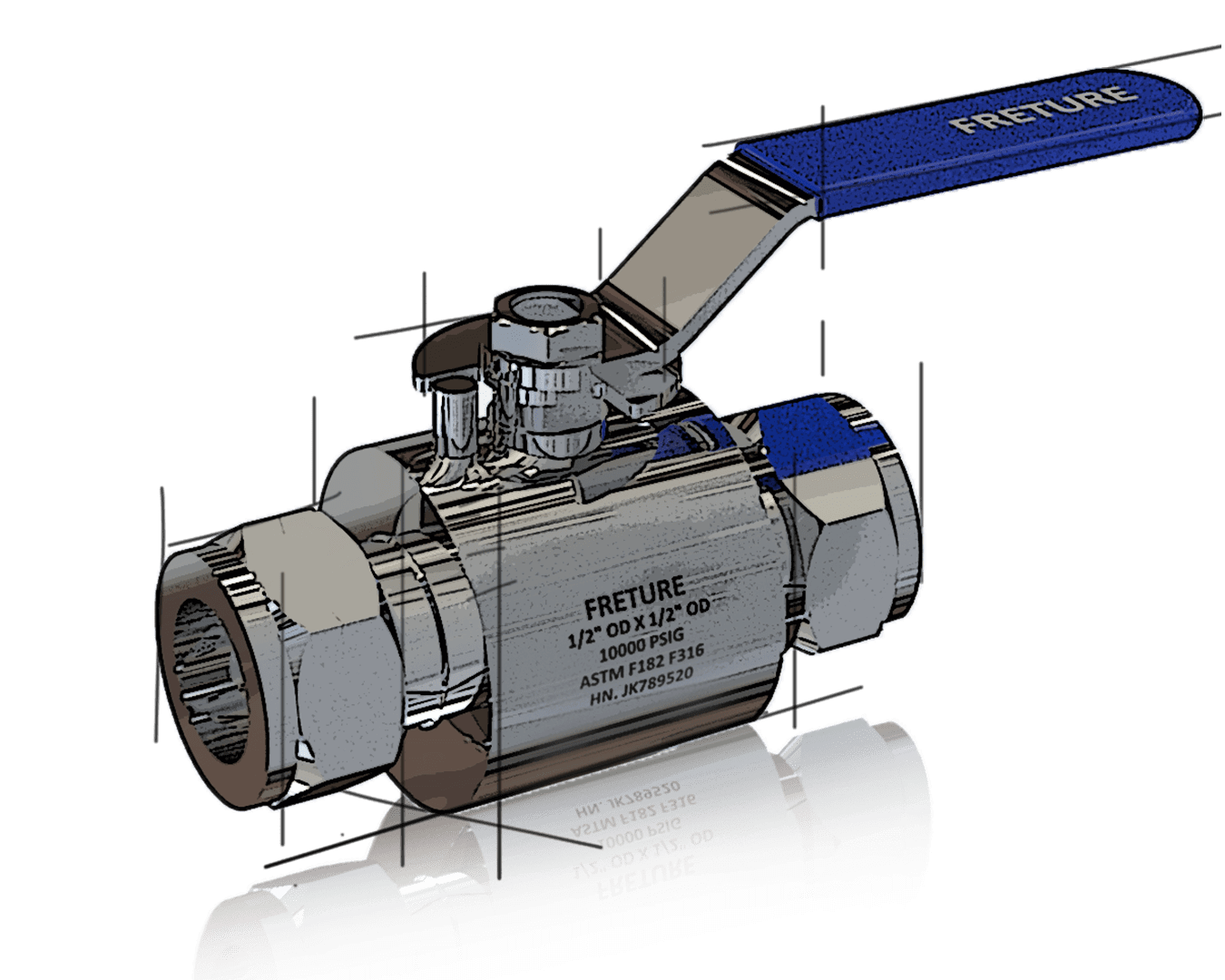

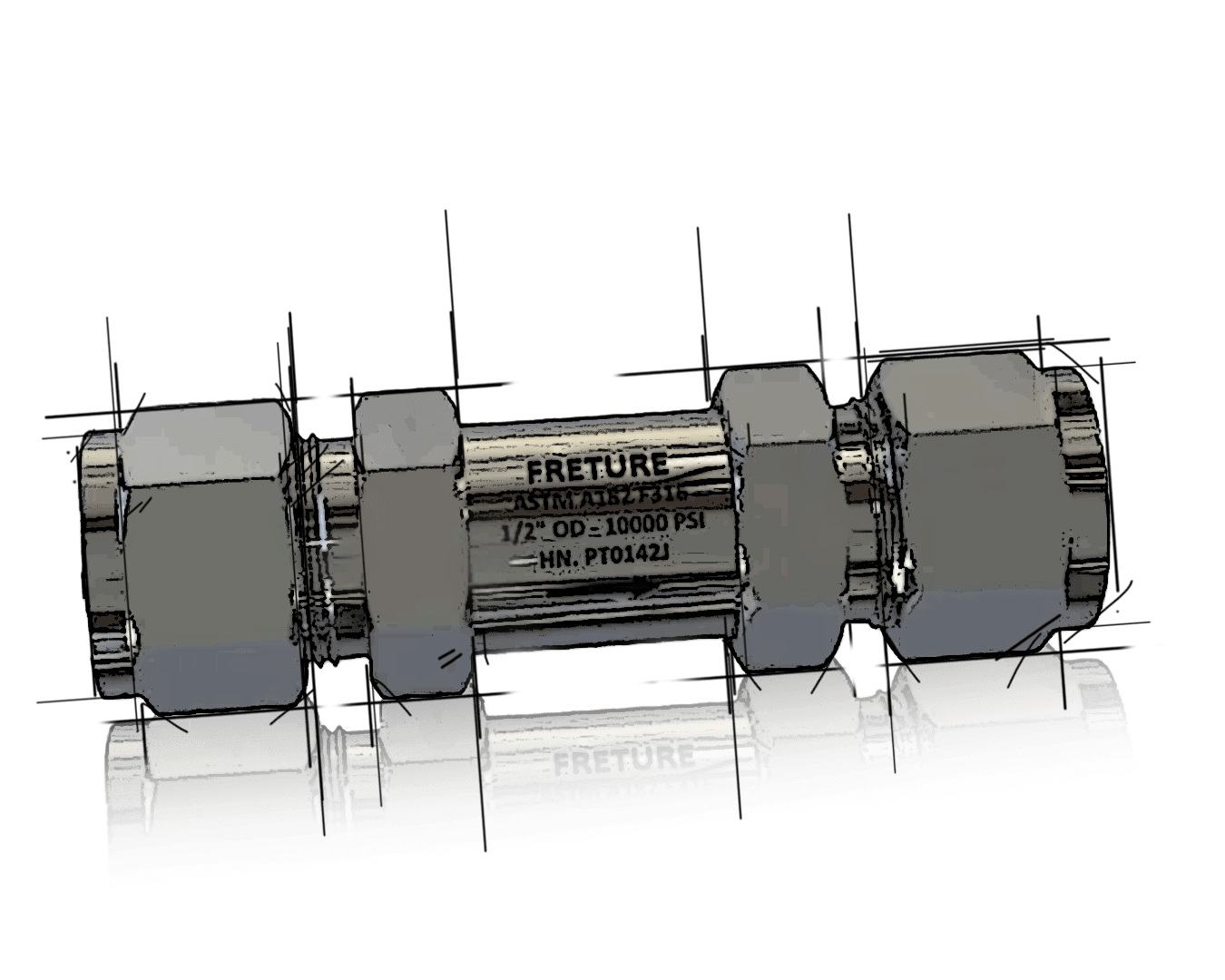

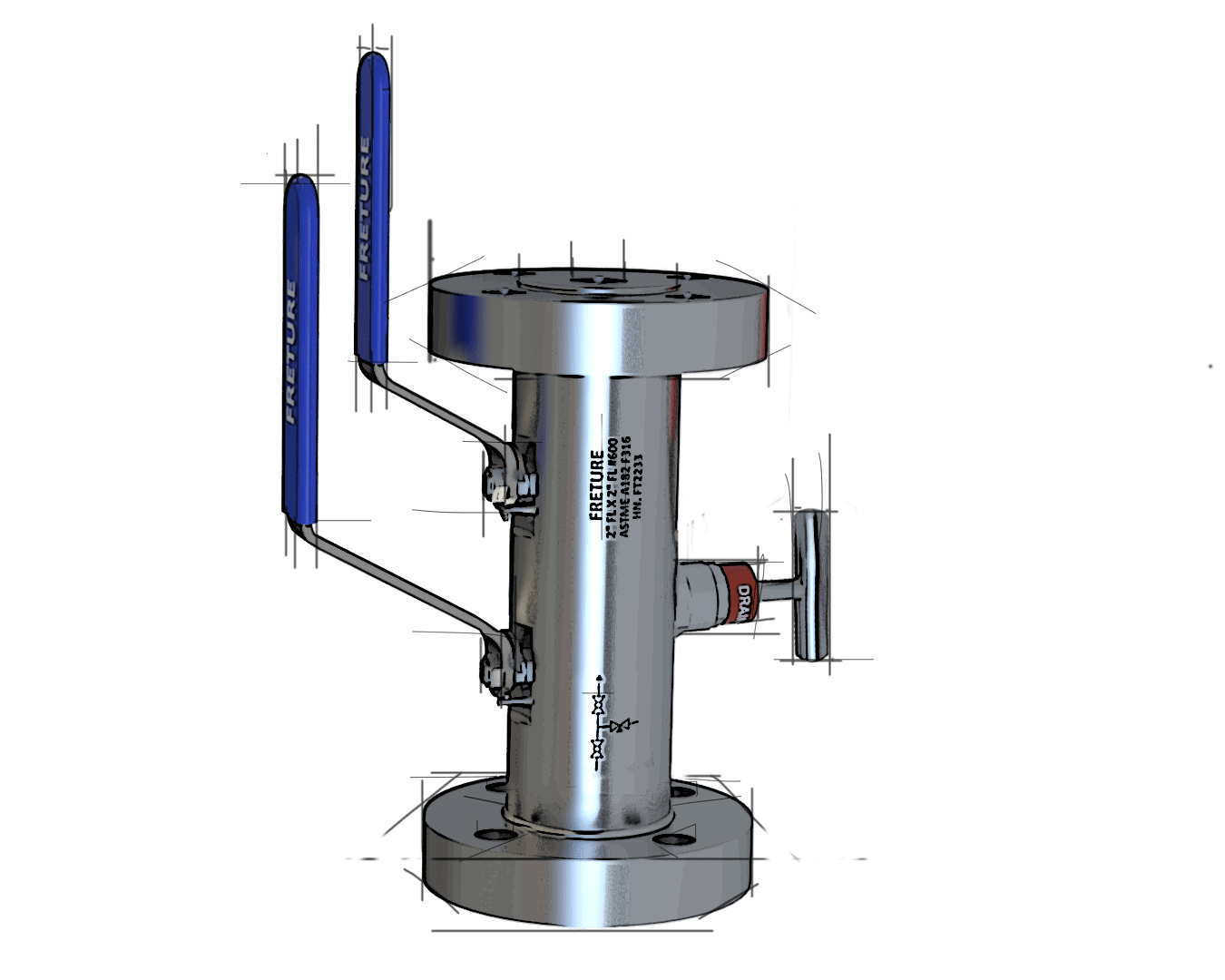

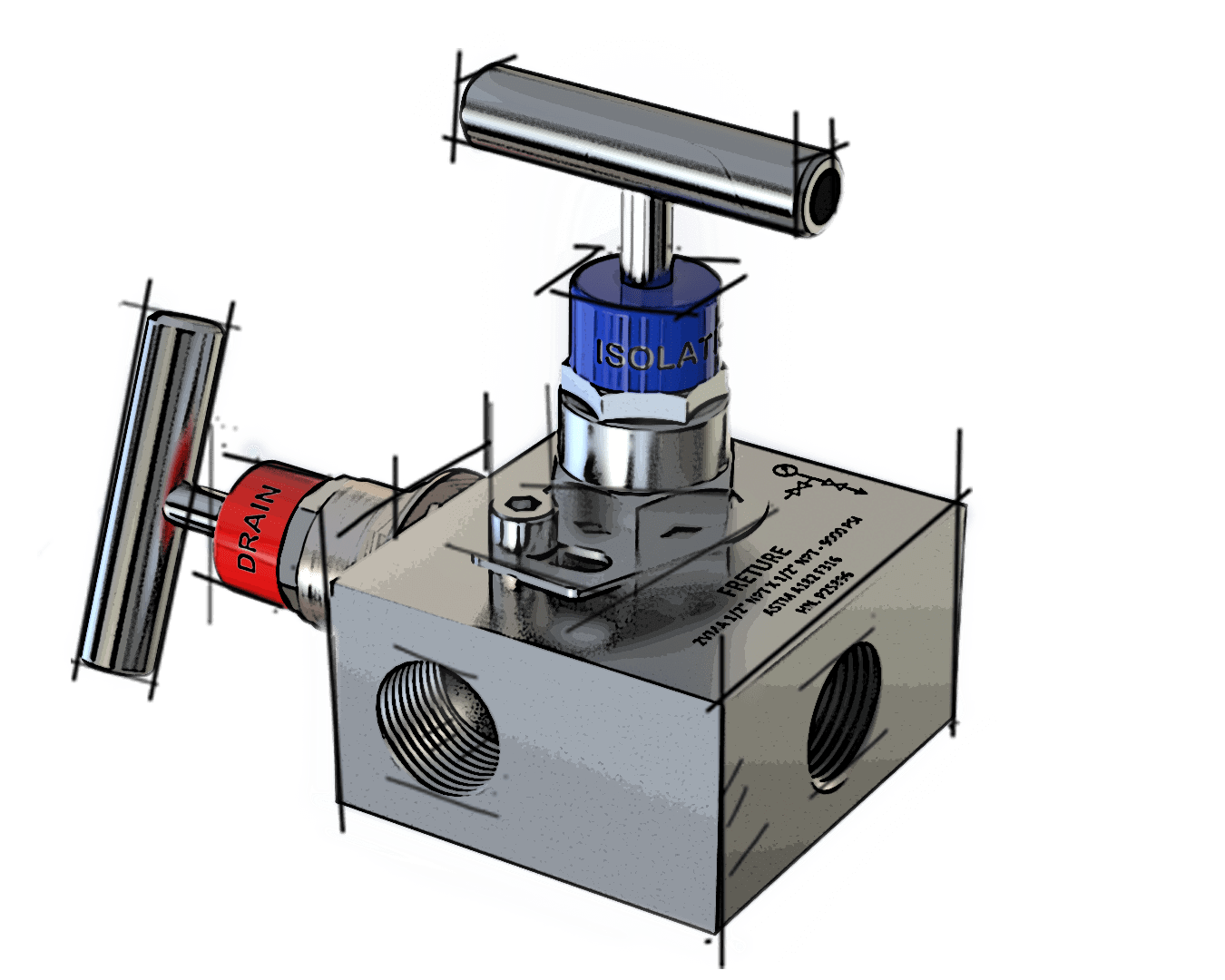

SS Needle valves are constructed from premium materials to ensure durability and reliability, including stainless steel (SS316, SS304), brass, and alloy for the body, stainless steel (SS316, SS304) for the stem, and PTFE or graphite for the packing. Key features of Needle Valves include precise flow control with a fine-threaded stem, high-pressure rating capable of withstanding up to 15,000 psi (1000 bar), and a wide temperature range from -65°F to 450°F (-54°C to 232°C) with PTFE packing, and up to 1200°F (649°C) with graphite packing. The corrosion-resistant materials ensure longevity in harsh environments, while the bubble-tight shutoff provides secure operations. High Pressure Needle Valves offer versatile end connections, including threaded, compression, flanged, and welded options, and a compact design that is space-saving for easy integration. Additionally, the replaceable seats extend valve life and reduce maintenance costs, and the fire-safe design meets API 607 and ISO 10497 standards. Easy operation is ensured with low torque and various handle types for user convenience.

High Pressure Needle Valves are manufactured to meet stringent industry standards, ensuring high quality and reliability, including ASME B16.34, API 598, ISO 9001, API 607, ISO 10497, and NACE MR0175/ISO 15156 for sour service. They are suitable for a wide range of applications across various industries, such as oil and gas, petrochemicals, chemical processing, power generation, water treatment, and instrumentation panels.

Fretuer stands out as a trusted High Pressure Needle valve manufacturer due to our rigorous quality assurance, precision engineering, and customization options to meet specific requirements, including variations in material, size, and end connections. With a global presence and a reputation for excellence, we serve diverse industries worldwide. Our dedicated customer support team provides prompt assistance and technical support for a seamless client experience. Choose Fretuer for premium Needle Valves that guarantee precision, reliability, and unmatched performance in critical industrial applications.

Description | Features |

|---|---|

TYPE: Straight / Anglular / Multi port End Connection: Threaded (NPT, BSPT, BSPP), Compression, Flanged, Welded (Socket Weld, Butt Weld) Size: 1/8” to 2” (DN 3 to DN 50) Pressure Rating: Up to 15,000 psi (1000 bar) Temperature Range: -54°C to 232°C (-65°F to 450°F) with PTFE packing, Up to 649°C (1200°F) with Graphite packing Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: ASME B16.34,ASME B16.11,ASME B1.20.1 Face to Face: ASME B16.10 Safety: NACE MOR 0175 , BS/EN 10204-3.1 REV 2004, API 598 Rev 2009, API-607 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Needle valve?

- How does it work?

They operates by rotating the valve stem, which in turn adjusts the position of the tapered needle. As the needle moves closer to or farther from the valve seat, the flow of fluid is regulated, allowing for precise control over flow rates.

- What are the benefits of using one

The advantages of Needle Valves include their exceptional flow control capabilities, even at low flow rates. They provide fine adjustments, leak-tight shut-off, and the ability to maintain stable pressure conditions, making them essential for processes requiring accuracy and stability

- What are the main applications?

They are commonly used in applications requiring precise flow control, such as instrumentation and control systems, laboratory equipment, hydraulic and pneumatic systems, and high-pressure and high-temperature applications.

- What materials are used in their construction?

They are typically constructed from materials such as stainless steel (SS316, SS304), brass, alloy 400, and PTFE (Teflon) for seals and packing.

- How do I choose the right one for my application?

To choose the right Needle Valve, consider factors such as pressure and temperature requirements, fluid compatibility, end connection type (threaded, flanged, compression, etc.), flow rate and system requirements, and construction material and corrosion resistance.

- Can they be repaired?

Yes, the valves can often be repaired. However, the repair process may vary depending on the extent of damage and the specific design of the valve. It is recommended to consult the manufacturer or a qualified technician for proper assessment and repair procedures.

- What maintenance is required?

Regular maintenance of this valves is essential to ensure optimal performance and longevity. Maintenance tasks may include regular inspection for wear and damage, lubrication of moving parts, and replacement of worn-out seals or components as needed.

- Are they available in different designs?

Yes, they are available in various designs to suit different application requirements, including inline needle valves, angle needle valves, integral bonnet needle valves, union bonnet needle valves, miniature needle valves, and hydraulic needle valves, among others.

- Why is Freture the best place to buy Needle Valves from?

Freture is the preferred choice for purchasing Needle Valves due to rigorous quality control measures ensuring adherence to international standards, precision engineering and customization options to meet specific requirements, global reputation for excellence and reliability in the manufacturing of High Pressure Needle valves, and responsive customer support and technical assistance ensuring a seamless experience for clients.

Industries where High Pressure Needle Valve is used

Oil & Gas Industry

Chemical Processing

Petrochemical Plants

Power Generations

Pharmacutical Industry

Applications of High Pressure Needle Valve

Instrumentation and Control Systems: They are commonly used in instrumentation and control systems where precise flow control is essential, such as pressure gauges, flow meters, and analytical instruments.

Laboratory Equipment: In laboratory settings, They are utilized for controlling the flow of various fluids in experiments, chromatography systems, and analytical instruments due to their ability to provide accurate and fine adjustments.

Hydraulic and Pneumatic Systems: They play a vital role in hydraulic and pneumatic systems by regulating the flow of hydraulic fluids and compressed air, ensuring precise control and efficient operation of the systems.

Process Control in Various Industries: They are widely used in various industries, including oil and gas, chemical processing, pharmaceuticals, and power generation, for process control applications that require accurate flow control in high-pressure and high-temperature environments.

High-Pressure and High-Temperature Applications: Due to their robust construction and precise flow control capabilities, needle valves are extensively employed in applications requiring control of high-pressure and high-temperature fluids, such as steam systems, boiler controls, and chemical processing plants.