A pressure gauge syphon is a device used to protect pressure instruments from high temperatures and corrosive media by condensing steam or cooling gases before they reach the gauge.

Pressure Gauge Syphon

Beat the Heat and Gaurd the gauges:Pressure Gauge Syphon

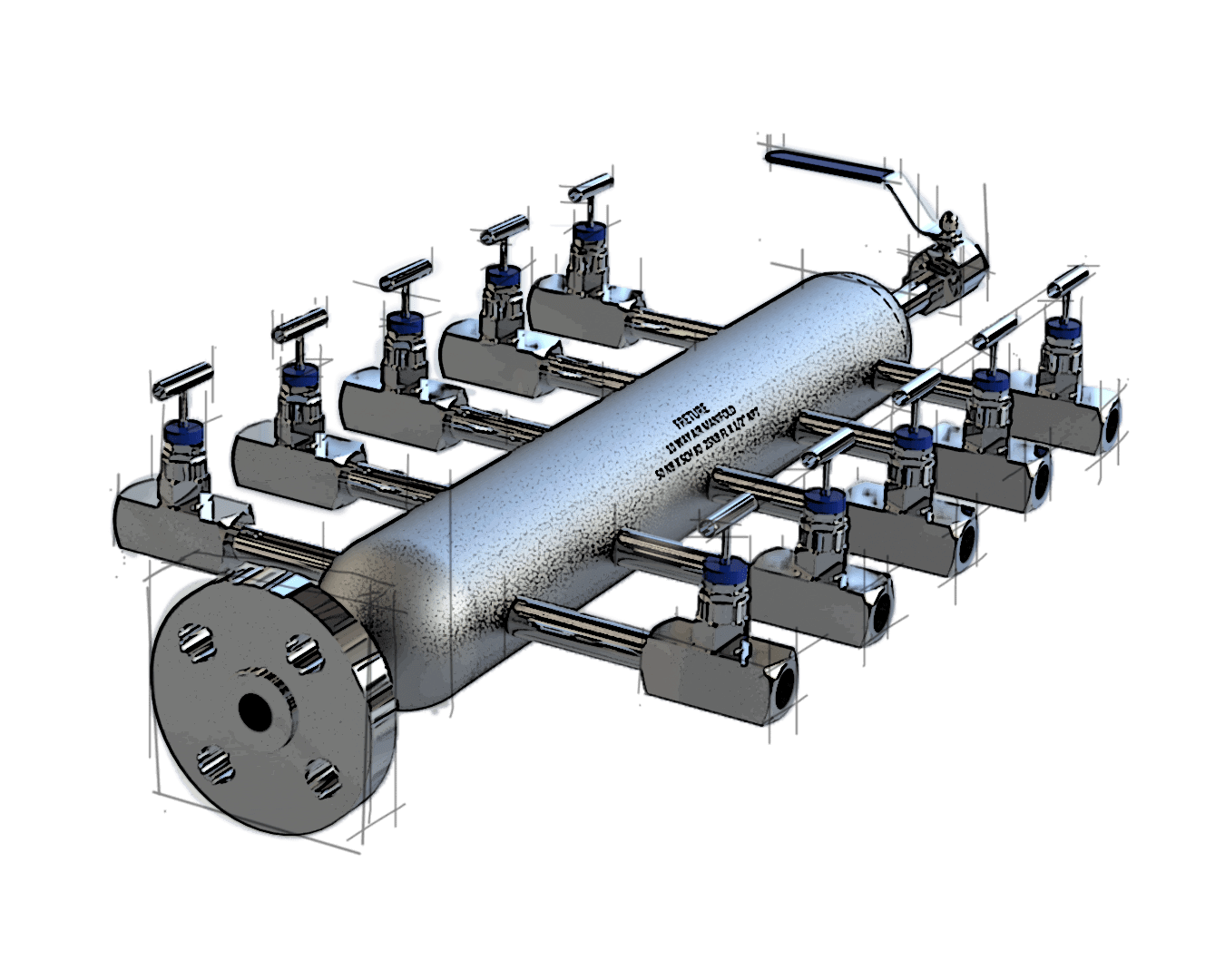

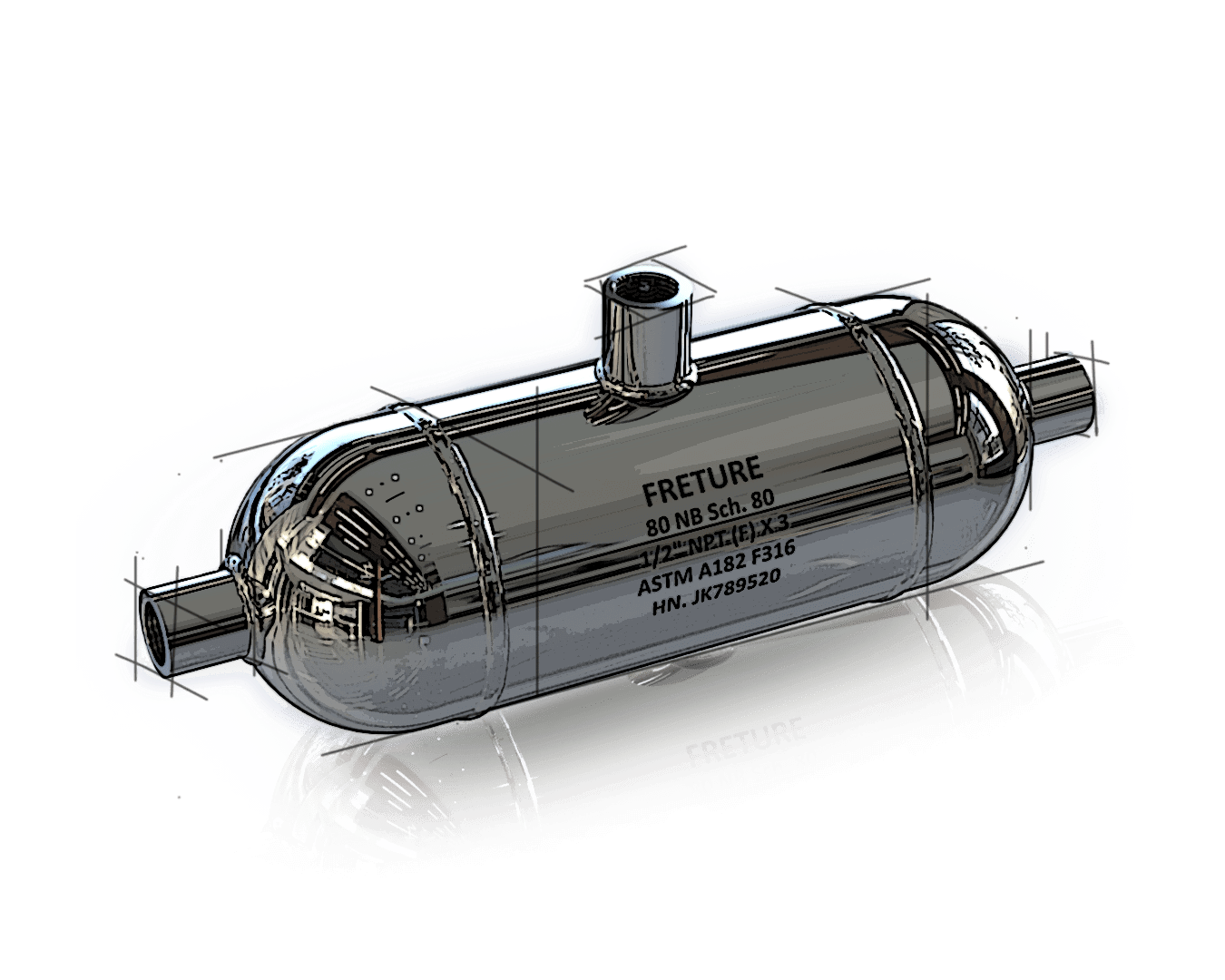

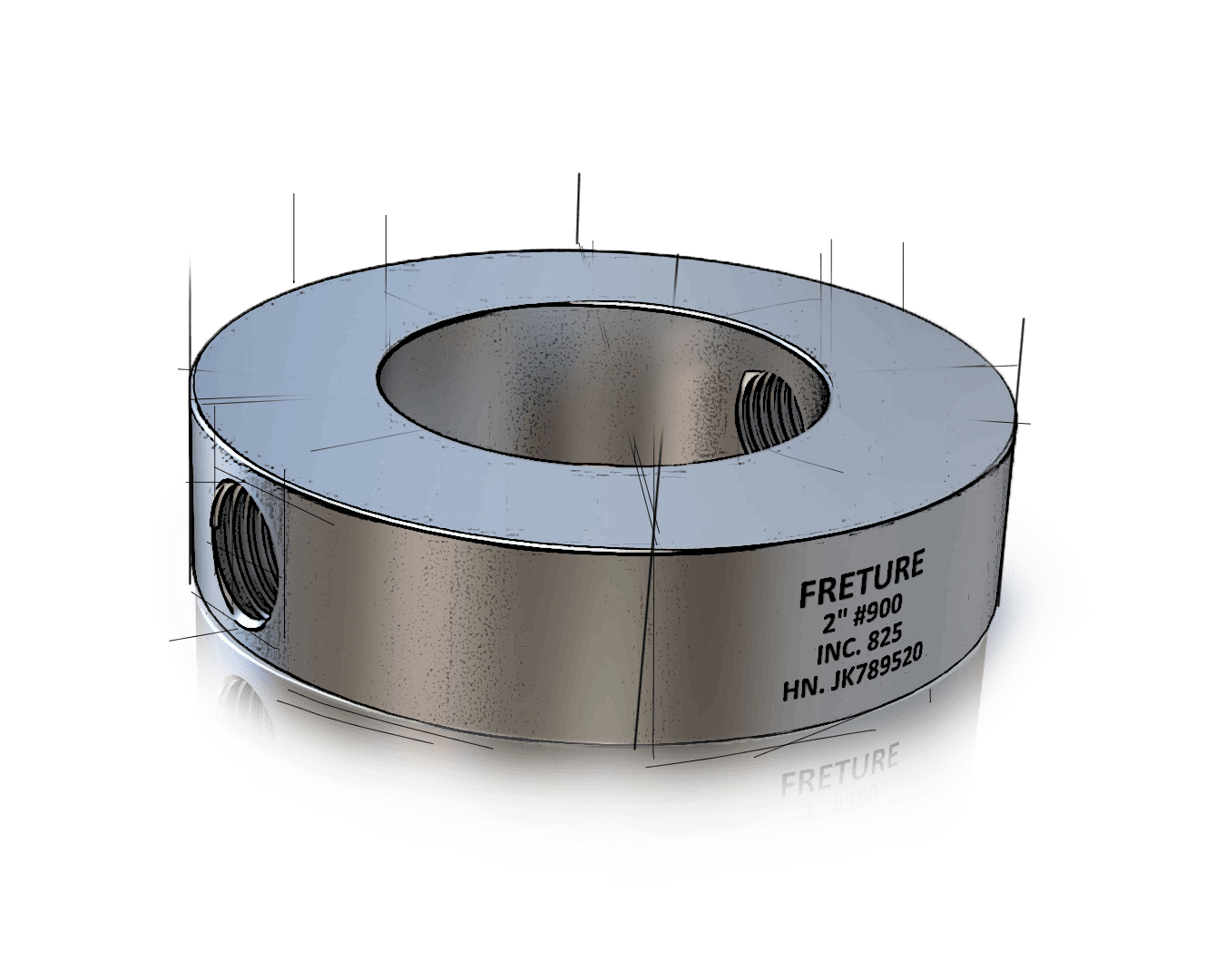

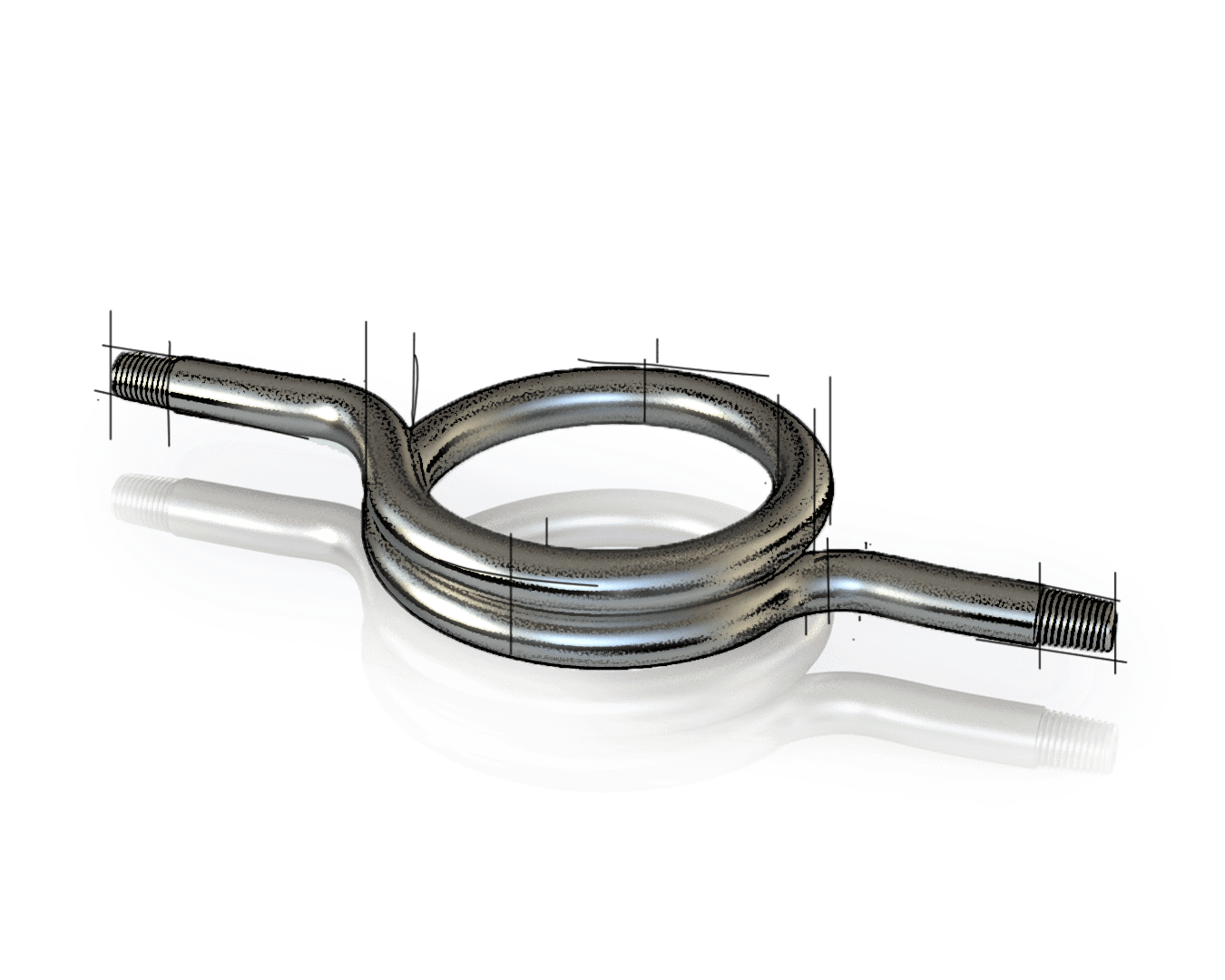

We are leading Pressure Gauge Syphon manufacturers in Mumbai, India. The Pressure Gauge Syphon designed to withstand high temperatures and corrosive media that could otherwise damage pressure gauges. By using the architecture of coiled tube or chamber filled with a cooling liquid such as water, syphons effectively condense high-temperature steam or gases before they reach the pressure gauge. This does not just, extends the lifespan of the gauge but also ensures accurate pressure measurement, critical for maintaining operational safety and efficiency

In industries like oil and gas, chemical processing, power generation, pharmaceuticals, food and beverage, water treatment, and HVAC systems. This Pressure Gauge Syphon pipe helps to prevent direct exposure of gauges to aggressive fluids or extreme temperatures, thus reducing maintenance costs, minimizing downtime, and enhancing overall system reliability. Their versatile applications make them indispensable in environments where precise pressure monitoring is near impossible.

Specifications | Features |

|---|---|

Type: Pressure Gauge Syphon Pipe End Connection: Flanged, Butt Weld/Socket Weld Size: Nominal Pipe Size (NPS) / Diameter Nominal (DN)/ Common sizes: 1/4", 1/2", 3/4" Pressure Rating: Up to 6000 psi (414 bar) Temperature: Operating range: -50°C to 500°C (-58°F to 932°F) Material: Carbon Steel, Stainless Steel, Alloy Steel Design Standard: ASME B31.3 (Process Piping) / ANSI/ASME B1.20.1 (Pipe Threads) /DIN standards (where applicable) Fire safe design: API 607 ISO 10497 Seat: PTFE / Metal-to-Metal /Graphite Safety: BS/EN, NACE,API 598 Rev 2009ISO 5208,API-607 Rev 2010 | Pressure Seal Design: Ensures tight sealing under high pressure. Integral Bonnet: Enhances structural integrity and safety. High Pressure Rating: Capable of withstanding high-pressure environments. Forged Construction: Provides strength and durability. Corrosion-resistant Coatings: Enhances durability in harsh environments. Bi-directional Sealing: Ensures sealing in both flow directions. Anti-Cavitation Trim: Mitigates damage from cavitation in high-velocity flow. Seal Welded Seat Ring: Prevents seat leakage under high pressure. Low Maintenance: Reduced need for frequent servicing. Safety Features: Helps prevent accidents and protects equipment from damage due to reverse flow. |

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a pressure gauge syphon?

- How does a pressure gauge syphon work?

It uses a coiled tube or chamber filled with a liquid such as water to cool or condense high-temperature steam or gas, thus preventing direct contact with the pressure gauge.

- When should a pressure gauge syphon be used?

Use syphons in applications involving steam, high-temperature gases, or corrosive fluids to protect gauges and ensure accurate pressure measurement without damaging the instrument.

- Where are pressure gauge syphons commonly used?

Pressure gauge syphons are commonly used in industries such as chemical processing, pharmaceuticals, and laboratories for tasks like draining vessels, transferring liquids between containers, and creating fluid flow in piping systems.

- What are the advantages of using pressure gauge syphon?

The primary advantages of Syphon Tubes include their simplicity of design, cost-effectiveness, and ability to transfer liquids without the need for external power sources.

- Are they available in different designs?

Yes, pressure gauge syphons come in various designs such as straight and pigtail configurations, each offering specific advantages for different applications and installation requirements.

- Can Pressure Gauge Syphon be customized for specific applications?

Yes, It customized in terms of material, length, and configuration to suit specific application requirements and environmental conditions.

- Can they be repaired?

Yes, not just can be repaired but can be reused in other applications.

- Do pressure gauge syphons require maintenance?

Regular inspection for blockages, leaks, and corrosion is recommended. Cleaning and ensuring the cooling liquid is replenished are typical maintenance tasks.

- Why is Freture the best place to buy it from?

As experienced valve and piping system manufacturers, buying from Freture offers advantages in quality of products to reliable customer service, and a commitment to satisfaction. Their range and expertise ensure you find the right solution for your needs.

Industries where Pressure Gauge Syphons is Used

Chemical Manufacturing

Oil & Gas Refineries

HVAC Systems

Pharmaceutical Industry

Power Generation

Applications of Pressure Gauge Syphons

- Power Generation: Monitoring steam pressure in boilers and turbines to ensure safety and efficiency in electricity generation.

- HVAC (Heating, Ventilation, and Air Conditioning): Monitoring pressure in HVAC systems to maintain optimal performance and energy efficiency in buildings.

Chemical Processing: Ensuring accurate pressure measurement in reactors, tanks, and chemical handling systems exposed to corrosive substances.

- Pharmaceutical: Maintaining precise pressure readings in sterile environments during drug manufacturing and packaging processes.