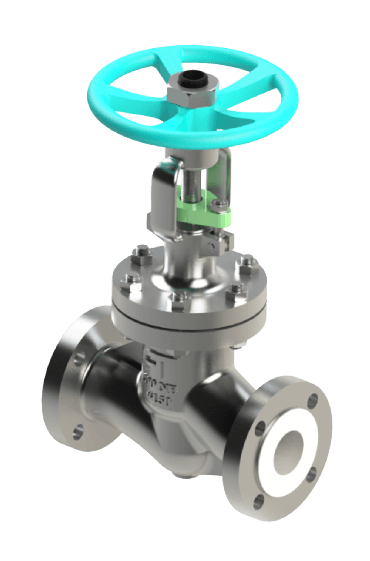

A Lined Valve is a type of valve that has an internal lining made of materials such as PTFE, PFA, or other corrosion-resistant polymers. This lining provides enhanced resistance to corrosive or abrasive media.

PTFE, PFA, FEP Lined Valves

Reliable Protection, Corrosion-Free Flow: Lined Valves for Demanding Applications

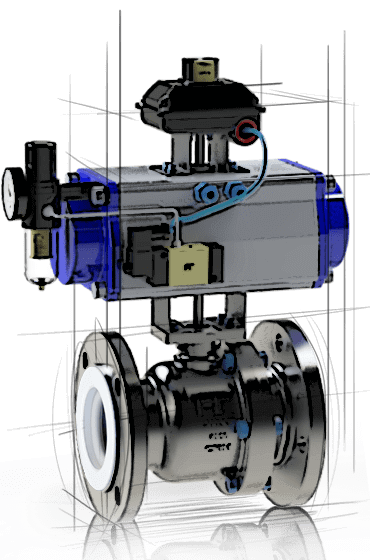

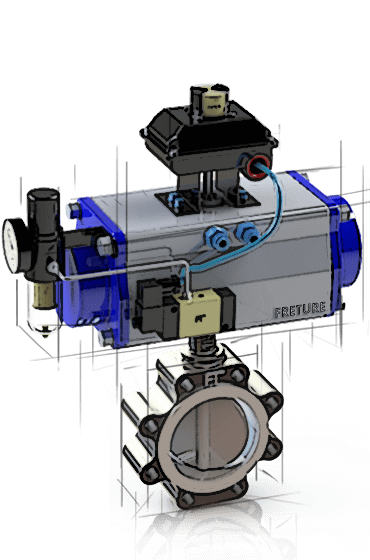

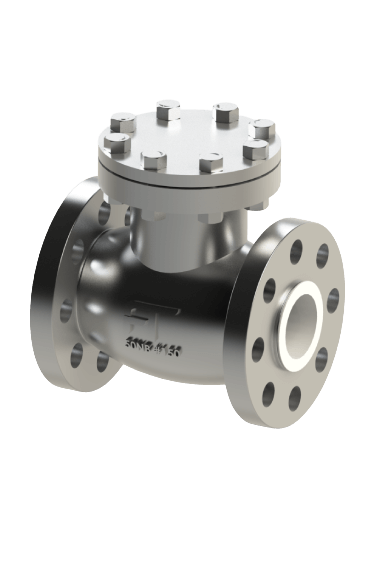

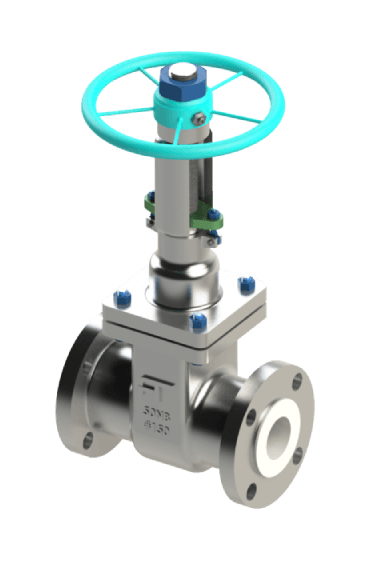

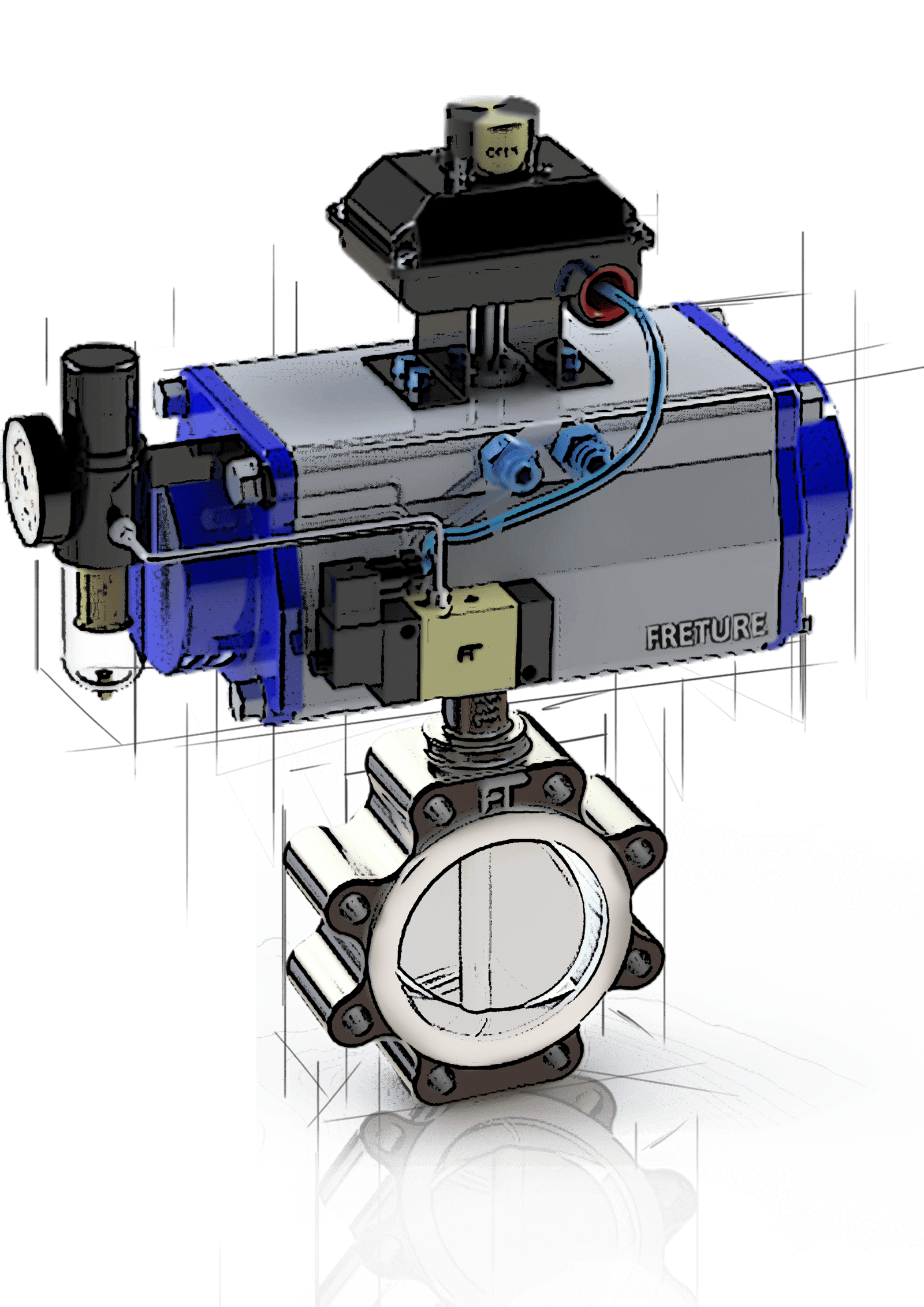

We are leading PTFE, PFA, FEP, PVDF Lined Valves Manufacturers in Mumbai, India. A Lined Valve is a specialized valve designed with an internal lining made from corrosion-resistant materials such as PTFE, PFA, or FEP, PVDF. This lining provides superior protection against corrosive, abrasive, and chemically aggressive media, ensuring long-term durability and reliable performance in challenging environments. Lined Valves are widely used in industries such as chemical processing, pharmaceuticals, food and beverage, water treatment, and petrochemicals. Their robust construction and exceptional resistance to chemical attack make them ideal for applications requiring stringent control over fluid purity and safety. Available in various designs, including Ball Valve, Butterfly Valve , Gate Valve, Globe Valve and Check valves, Lined Valves offer versatile solutions for controlling fluid flow in demanding applications.

Lining materials used inside valves, such as PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), and FEP (Fluorinated Ethylene Propylene), have become essential for industries dealing with corrosive or abrasive media. These materials provide a protective barrier between the valve’s metal body and the process fluid, offering exceptional resistance to harsh chemicals, high temperatures, and wear. Lined valves are especially valuable in industries like chemical processing, pharmaceuticals, and water treatment, where traditional metal valves would quickly corrode or degrade. The popularity of lined valves stems from their ability to extend equipment life, reduce maintenance costs, and ensure safer, more reliable operations in environments where process fluids can be highly reactive or aggressive. This combination of durability, cost-effectiveness, and enhanced operational safety has made lined valves a preferred choice across various sectors that require consistent performance under challenging conditions.

For high-quality lined valves that offer unmatched reliability and performance, buy from Freture Techno Pvt. Ltd., a leading manufacturer committed to excellence in industrial valve solutions.

Explore Types of PTFE, PFA, FEP Lined Valves

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Lined Valve?

- How does a Lined Valve work?

A Lined Valve functions similarly to traditional valves but with an added layer of corrosion-resistant material on its internal surfaces. This lining protects the valve body from aggressive media, ensuring reliable operation and extended service life.

- What are the main applications?

They are primarily used in industries such as chemical processing, pharmaceuticals, food and beverage, water treatment, and petrochemicals. They are ideal for handling corrosive, toxic, or abrasive fluids.

- What are the benefits of using a Lined Valve?

Benefits include superior corrosion resistance, extended service life, reduced maintenance costs, compatibility with a wide range of chemicals, and improved safety when handling hazardous materials.

- What materials are used in Lined Valves?

Mostly linings made of PTFE (Polytetrafluoroethylene), PFA (Perfluoroalkoxy), FEP (Fluorinated Ethylene Propylene), and other corrosion-resistant polymers. The valve body is usually made of materials like stainless steel, carbon steel, or ductile iron.

- How do I choose the right Lining for my application?

Consider the type of media, operating temperature and pressure, flow rate requirements, and compatibility with the lining material. Consulting with a valve specialist can help ensure the right selection for your specific application.

- Can Lined Valves be repaired?

Yes, They can be repaired. However, due to the specialized nature of the lining materials, repairs should be conducted by qualified professionals or the manufacturer to maintain the integrity and performance of the valve.

- What maintenance is required for these Valves?

Usually, require minimal maintenance due to their corrosion-resistant properties. Regular inspections and cleaning are recommended to ensure optimal performance and to check for any signs of wear or damage.

- Are Lined Valves available in different designs?

Yes, They are available in various designs, including ball valves, butterfly valves, plug valves, and diaphragm valves, to suit different application requirements.

- Why is Freture the best place to buy lined valves from?

- High Quality: Superior materials like PTFE, PFA, and FEP.

- Wide Selection: Various designs for different industry needs.

- Expert Support: Knowledgeable staff for optimal valve selection.

- Competitive Pricing: Excellent value for high-quality products.

- Customer Satisfaction: Strong after-sales support and reliable warranty.

Industries where PTFE, PFA Lined Valve is Used

Chemical Manufacturing

Pharmaceutical Industry

Food and Beverage

wastewater management

Petrochemical Industry

Applications of PTFE, PFA and FEP Lined valves:

- Chemical Processing: Handle corrosive and reactive chemicals safely.

- Pharmaceutical Industry: Ensures purity and prevents contamination.

- Food and Beverage Industry: Maintains hygiene and resists chemical cleaning agents.

- Water Treatment: Controls corrosive media and aggressive chemicals.

- Petrochemical Industry: Manages aggressive fluids and gases in harsh environments.