A Butterfly Ball Valve is a type of valve that combines the functionality of both a butterfly valve and a ball valve. It features a spherical ball with a through-hole, similar to a traditional ball valve, but with butterfly-style quarter-turn operation.

Butterfly Valve

A butterfly valve is from a family of valves called quarter-turn valves.

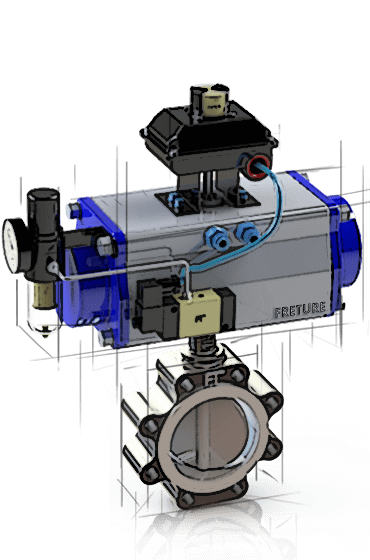

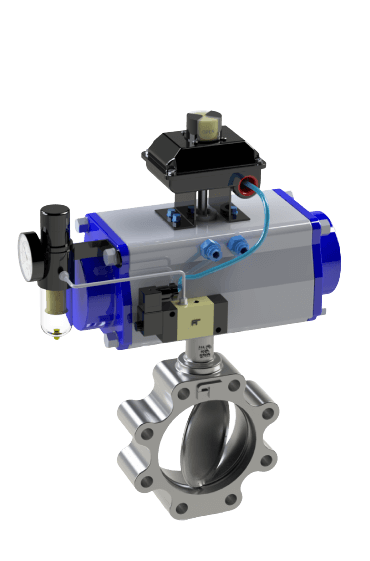

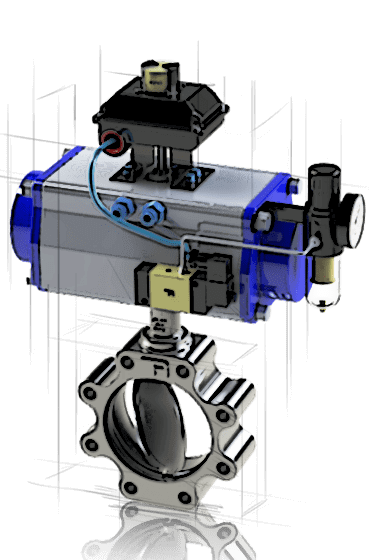

Freture Techno Pvt. Ltd. stands out as a premier butterfly valve manufacturer in Mumbai, India, renowned for exceptional design and production of high-quality butterfly valves catering to diverse industrial needs. Utilizing top-grade materials, their valves guarantee superior performance and reliability. Customized solutions are a forte, aligning with specific customer requirements. With offerings in varying sizes, materials, and designs, Freture Techno accommodates a wide array of applications, coupled with outstanding customer service and technical support, ensuring utmost satisfaction.

Standing at the forefront among the best butterfly valve manufacturers in Mumbai, India Freture Techno Pvt. Ltd. excels in delivering a comprehensive range of butterfly valves in different sizes and types, finely crafted for distinct industrial applications. Leveraging advanced technology and superior materials, they present butterfly valves of exceptional durability and reliability, available in both manual and automated versions. The company also offers bespoke butterfly valves tailored to clients' specifications. Their butterfly valves find extensive use in industries such as water supply, petrochemicals, oil & gas, food & beverages, and more.

Freture Techno Pvt. Ltd. holds a prominent position as one of the leading providers of top-tier butterfly valve manufacturing in Mumbai, India. Their extensive lineup includes standard, high-performance, and tailor-made butterfly valves, each meticulously designed to meet the highest quality standards. Crafted with precision and tested for consistent performance and reliability, these valves find applications in diverse industrial settings, both on-site and off-site. Complementing their valve range, they offer a variety of accessories and spare parts to enhance performance and prolong the valves' lifespan. Technical guidance and support further ensure optimal and cost-effective utilization of our products.

Earning a solid reputation as a top butterfly valve manufacturer in Mumbai, Freture Techno Pvt. Ltd. has built trust and loyalty over many years by delivering high-quality products such as Concentric Design Butterfly Valve, Single Offset Butterfly Valve, Double Offset Butterfly Valve and Lined Butterfly Valve. As an ISO 9001:2015 certified company, they are committed to offering premium products at competitive market prices. Employing cutting-edge technology and materials, their butterfly valves adhere to the industry's highest standards, emphasizing superior performance, reliability, and longevity. The product range encompasses Wafer Type Butterfly Valves, Lug Type Butterfly Valves, High-Performance Butterfly Valves, and more, available in various sizes and materials. All products undergo rigorous testing and certification, and customization options ensure a precise fit for specific requirements.

Description | Features |

|---|---|

TYPE: Concentric Design / Single / Double / Lug / Wafer End Connection: Wafer / Lug / Flanged Size: 2" (50mm) to 24" (600mm) Class: 150# - 600# Temperature Range: -20°C to 200°C MOC: Carbon Steel, Stainless Steel, Cast Iron Design Standard: API 609, EN 593 Face to Face: API 609, EN 558 End Connection Std.: ASME B16.5, EN 1092 Fire safe design: API 607, ISO 10497 Testing: API 598 Sour Service: NACE MR0175 Documents: Material Test Certificate (MTC), Certificate of Compliance (CoC) |

|

Explore Types of Butterfly Valves

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Butterfly Ball Valve?

- How does it work?

It operates by using a spherical ball with a hole through the middle, similar to a standard ball valve. However, instead of a traditional valve stem, it utilizes a butterfly-style actuator for quarter-turn operation.

- What are the main applications?

Main applications include water and wastewater treatment, HVAC systems, chemical processing, and general fluid control applications requiring moderate pressure and temperature ratings.

- What are the benefits of using one?

Benefits include compact design, low torque operation, excellent flow control, and versatility in various fluid control applications.

- What materials are used in their construction?

Butterfly Ball Valves are typically constructed from materials such as stainless steel, carbon steel, cast iron, and various thermoplastics, depending on the specific application requirements.

- How do I choose the right one for my application?

Choose based on factors such as the type of fluid, pressure rating, temperature range, valve size, end connections, and compatibility with the specific application requirements to ensure optimal performance.

- Can they be repaired?

Yes, Butterfly Ball Valves can be repaired. Common repairs may include replacing seals, bearings, or other components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage.

- Are they available in different designs?

Yes, Butterfly Ball Valves are available in various designs, including different sizes, end connections, and actuation methods to meet diverse application needs.

- Why is Freture the best place to buy from?

Freture offers high-quality Butterfly Ball Valves, backed by expert engineering, extensive industry experience, and a commitment to customer satisfaction. Our products are reliable, competitively priced, and tailored to meet the specific needs of your applications.

Industries where Butterfly Valve is Used

Water Treatment Industry

HVAC Industry

Chemical Processing

Oil and Gas Industry

Power Generation Industry

Application of Butterfly Valve

- Water Management: Regulating flow in water systems.

- HVAC Systems: Controlling air and water flow.

- Chemical Processing: Handling corrosive fluids.

- Oil and Gas Pipelines: Flow Control and Isolation.

- Power Plants: Controlling water and steam flow.