A Lined Gate Valve is a type of valve with an internal lining of corrosion-resistant material, designed to control the flow of corrosive or abrasive fluids.

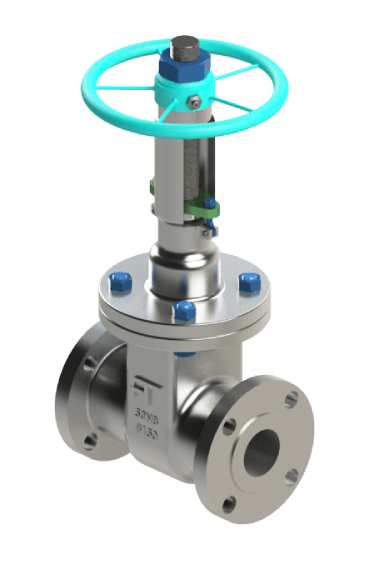

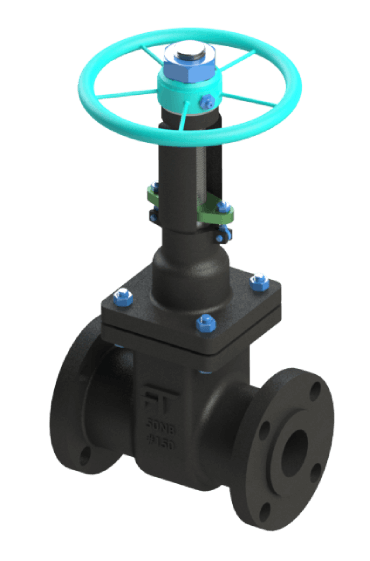

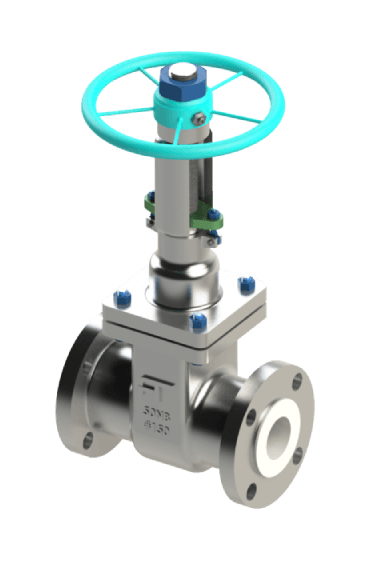

PTFE Lined Gate Valve

Freture Techno leading PFA / FEP / PTFE Lined Gate Valve manufacturer, supplier, and exporter in Mumbai, India. When it comes to precision and reliability in fluid control systems, nothing quite matches the performance of FEP / PFA / PTFE Lined Gate Valves. These valves, engineered with utmost precision, are designed to provide unparalleled control over the flow of various corrosive and abrasive media. Whether you're in the chemical industry, petrochemical sector, or any application where harsh fluids are handled, Lined Gate Valves are the ultimate choice for your fluid control needs.

Key Features of Lined (PTFE / FEP / PFA ) Gate Valves :

Corrosion Resistance: Lined Gate Valves are constructed with a lining made of chemically resistant materials like PTFE (Polytetrafluoroethylene), ensuring long-lasting protection against corrosive substances.

Tight Shutoff: These valves offer a reliable, bubble-tight seal, preventing leakage and ensuring that your processes remain efficient and secure.

Smooth Flow Control: The design of FEP / PFA / PTFE Lined Gate Valves allows for precise modulation of fluid flow, making them ideal for applications where flow control is critical.

Durable Construction: Crafted with durable materials and designed for longevity, these valves can withstand the rigors of demanding industrial environments.

Versatile Use: PTFE / FEP / PFA Lined Gate Valves find applications in a wide range of industries, including pharmaceuticals, chemicals, water treatment, and more.

Low Maintenance: With their robust design and minimal moving parts, these valves require minimal maintenance, reducing downtime and operational costs.

Why Choose Freture Techno as Your FEP / PFA / PTFE Lined Gate Valve Manufacturer in Mumbai, India?

At Freture Techno, we pride ourselves on being one of the leading Lined Gate Valve manufacturers in Mumbai, India. Our commitment to quality, precision, and customer satisfaction sets us apart in the industry.

Expertise: With years of experience in fluid control technology, our team of experts understands the unique demands of different industries and can provide tailored solutions to meet your specific requirements.

Cutting-Edge Technology: We employ state-of-the-art manufacturing processes and technology to ensure that FEP / PFA / PTFE Lined Gate Valves meet the highest standards of quality and performance.

Customization: We offer a wide range of customization options to tailor our Lined Gate Valves to your unique applications, ensuring that you get the perfect solution for your needs.

Quality Assurance: Our valves undergo rigorous quality control and testing processes to guarantee their reliability and durability in your operations.

Timely Delivery: We understand the importance of timelines in your projects. Freture Techno is committed to delivering your PTFE / FEP / PFA Lined Gate Valves promptly and efficiently.

Choose Freture Techno as your trusted partner for PTFE / FEP / PFA Lined Gate Valves, and experience unmatched fluid control precision, reliability, and quality. Contact us today to discuss your requirements and discover how our expertise can enhance your fluid control systems.

Specifications | Features |

|---|---|

Type: Lined Gate Valve End Connection: Flanged ( ASME B16.5 ) Size: 15NB - 600NB Pressure Rating Class: 150# - 2500# Temperature Range: -7° C to 200° C Body Material: Carbon Steel / Stainless Steel / Alloys Design Standard: API 600 / 603 / ASME B 16.34 Lining Material: PTFE, PFA, FEP, PVDF, Polypropylene, or other suitable materials Face to Face: ANSI B16.10 Rev 2009 Operation: Manual / Gear / Motorised / Actuated Safety: NACE, BS/EN 10204-3.1 REV 2019, API 6FA, API 598 Rev 2009 / ISO 15848 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is a Lined Gate Valve?

- How does it work?

It operates by raising or lowering a gate inside the valve body to open or close the flow path, providing a tight seal when closed.

- What are the main applications?

Lined Gate Valves are primarily used in chemical processing, water treatment, pharmaceuticals, and other industries handling corrosive or abrasive fluids.

- What are the benefits of using one?

Benefits include excellent corrosion resistance, a tight seal, durability, and the ability to handle aggressive fluids without damage to the valve body.

- What materials are used in their construction?

Common materials include a metal body (such as stainless steel) lined with corrosion-resistant materials like PTFE, PFA, or FEP.

- How do I choose the right one for my application?

Consider factors like fluid type, temperature, pressure, valve size, and compatibility with the corrosive or abrasive nature of the fluid.

- Can they be repaired?

Yes, Lined Gate Valves can be repaired, typically by replacing the lining or other worn components.

- What maintenance is required?

Regular maintenance includes inspecting the lining for wear, checking for leaks, and ensuring the gate mechanism operates smoothly.

- Are they available in different designs?

Yes, they come in various designs to accommodate different applications, including different linings and actuation methods.

- Why is Freture the best place to buy from?

Freture is the best choice due to our commitment to quality, extensive industry experience, expert technical support, and a wide range of high-quality lined gate valves tailored to meet specific customer needs.

Industries where PTFE Lined Gate Valve is Used

Chemical Processing

Water Treatment

Pharmaceutical Industry

Pulp and Paper Industry

Refineries

Application of Lined PTFE Gate Valve

- Chemical Processing: for handling corrosive chemicals.

- Water treatment: regulating corrosive and abrasive fluids.

- Pharmaceuticals: managing sterile or corrosive fluids.

- Pulp and Paper: Controlling Corrosive Chemicals and Slurries.

- Refineris: handling abrasive slurries and corrosive fluids.