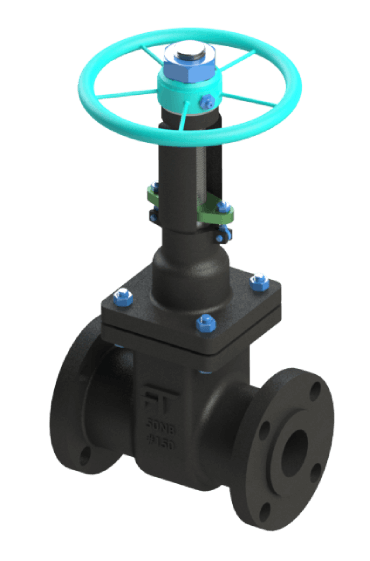

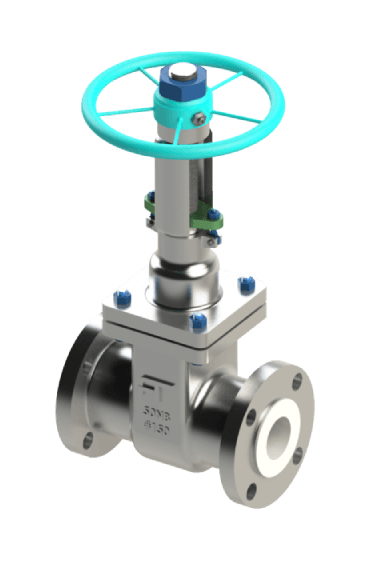

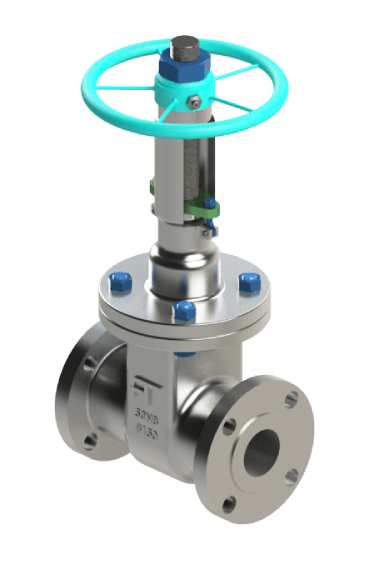

An API 600 Gate Valve is a type of gate valve designed and manufactured according to the standards set by the American Petroleum Institute (API). API 600 covers larger gate valves for general industrial use, while API 602 covers smaller, forged gate valves typically used in high-pressure, high-temperature applications.

API 600 Gate Valve

Precision, Performance, Freture Techno: Your API Gate Valve Experts

We are the Leading API Gate Valve Manufacturer, supplier, and exporter in Mumbai, India. In the realm of fluid control solutions, API Gate Valves stand as stalwarts of reliability and performance. Designed and crafted to adhere to stringent industry standards set by the American Petroleum Institute (API), these valves are engineered to handle high-pressure and high-temperature applications with unparalleled precision. Whether you're operating in the oil and gas sector, chemical processing, or any industry that demands robust fluid control, API Gate Valves from Freture Techno are the epitome of excellence.

Key Features of API 600 Gate Valves:

- API-Compliant: Our API Gate Valves strictly adhere to API standards, ensuring compliance with the industry's most rigorous quality and safety requirements.

- High Pressure-Temperature Rating: Built to withstand extreme conditions, these valves are engineered for applications where pressure and temperature levels can be unforgiving.

- Durable Construction: Crafted from high-quality materials, our API Gate Valves are built to last, ensuring uninterrupted operations and longevity.

- Leak-Tight Seal: These valves provide a dependable, leak-tight seal, safeguarding your processes from costly and potentially hazardous leaks.

- Precise Flow Control: With their precision-engineered design, API Gate Valves offer exceptional control over fluid flow, making them ideal for critical applications.

- Wide Application Range: Versatility is at the core of these valves, making them suitable for diverse industries, including oil and gas, petrochemicals, power generation, and more.

- Minimal Maintenance: Their robust design minimizes wear and tear, reducing maintenance needs and operational costs.

Why Choose Freture Techno as Your API Gate Valve Manufacturer?

At Freture Techno, we go beyond manufacturing API Gate Valves; we deliver reliability, precision, and peace of mind to our valued customers.

- Expertise: With a team of seasoned professionals who possess extensive knowledge of API standards, we are well-equipped to provide you with top-tier API Gate Valves tailored to your specific requirements.

- Cutting-Edge Technology: We leverage advanced manufacturing processes and technology to produce API Gate Valves that meet and exceed industry expectations.

- Custom Solutions: We understand that no two applications are alike. Freture Techno offers customization options to ensure our API Gate Valves seamlessly integrate with your unique systems.

- Quality Assurance: Our commitment to quality is unwavering. Every API Gate Valve from Freture Techno undergoes rigorous testing to guarantee reliability and performance in your operations.

- Timely Delivery: We value your time. Our streamlined processes ensure prompt and efficient delivery of your API Gate Valves, so you can keep your projects on track.

Choose Freture Techno as your trusted partner for API Gate Valves and experience the pinnacle of fluid control precision, reliability, and quality. Contact us today to discuss your requirements and witness firsthand how our expertise can elevate your fluid control systems.

Specifications | Features |

|---|---|

TYPE: Gate Valve End Connection: Flange (B16.5) / Butt Weld (B16.25) / Socket Weld (B-16.11) Size: 15 NB - 600 NB Class: 150# –2500# Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: API 600 Face to Face: ASME B16.10 Rev 2009 Operation: Manual / Gear / Motorised / Actuated Safety: BS/EN 10204-3.1 REV 2019, API 6FA, API 598 Rev 2009 / ISO 15848 |

|

Related Products

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- What is an API 600 Gate Valve?

- How does it work?

A gate valve operates by raising or lowering a gate (or wedge) to open or close the flow of fluid. When the gate is lifted, fluid can flow through; when it is lowered, it blocks the flow, providing a tight seal.

- What are the main applications?

Main applications include oil and gas production, petrochemical processing, power generation, and water treatment, where reliable flow control and isolation are critical.

- What are the benefits of using one?

Benefits include robust construction, reliable sealing, suitability for high-pressure and high-temperature environments, minimal pressure drop when fully open, and long service life.

- What materials are used in their construction?

These valves are typically constructed from materials such as carbon steel, stainless steel, alloy steel, and other high-performance alloys to withstand harsh operating conditions.

- How do I choose the right one for my application?

Choose based on factors such as the type of fluid, pressure and temperature requirements, valve size, end connection type, material compatibility, and specific industry standards relevant to your application.

- Can they be repaired?

Yes, API 600 Gate Valves can be repaired. Common repairs include replacing worn seals, gaskets, and other internal components to restore functionality and maintain a tight seal.

- What maintenance is required?

Regular maintenance includes periodic inspection, cleaning, lubrication of moving parts, and replacement of worn or damaged components to ensure reliable operation and extend the valve's service life.

- Are they available in different designs?

Yes, these valves are available in various designs, including different sizes, pressure ratings, end connections, and actuation methods to meet diverse application needs.

- Why is Freture the best place to buy from?

Freture is the best choice for purchasing API 600 Gate Valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. We offer high-quality valves, expert technical support, and competitive pricing, ensuring reliable solutions tailored to your specific needs.

Industries where Industrial Gate Valve is Used

Oil and Gas Industry

Petrochemical Industry

Power Generation Industry

Chemical Processing Industry

Water Treatment Industry

Application of API 600 Gate Valves

- Flow Control in Pipelines: Regulating and Isolating Flow in Oil and Gas Pipelines.

- Petrochemical Plants: Managing Fluids in Chemical Processing Units.

- Power Plants: Controlling steam and water flow in power generation systems.

- Water Treatment: Isolating and directing flow in water treatment facilities.

- Refineries: Handling high-pressure and high-temperature fluids in refining processes.