These valves work by using a disc or plug mechanism to control the flow of fluid through the bottom outlet. When actuated, the valve opens or closes, allowing for drainage or sealing of the vessel.

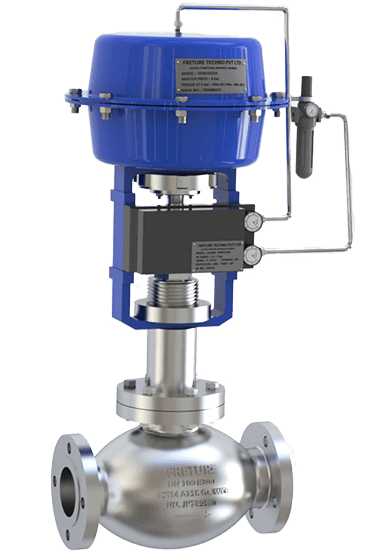

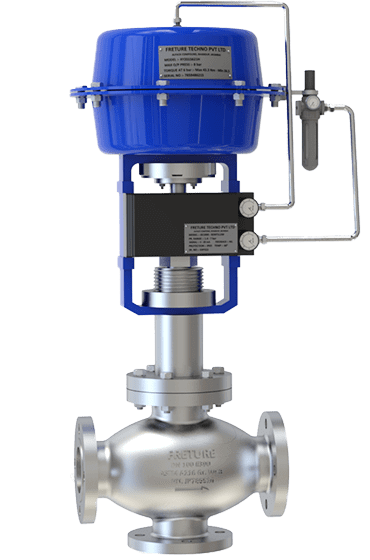

Flush Bottom Valve

FRETURE is a leading Flush Bottom Valves manufacturer in Mumbai, India, adhering to the highest manufacturing standards. Flush Bottom Valves are designed and engineered to meet stringent industry requirements, ensuring optimal performance and reliability.

What is a Flush Bottom Control Valve?

It is a specialized type of valve used in industries where thorough cleaning and draining of the system are essential. It features a unique design with the valve body mounted flush with the bottom of the vessel or tank, allowing complete drainage and minimizing product buildup. This design prevents contamination and ensures efficient cleaning processes.

Types of Flush Bottom Control Valve

FRETURE offers various types of Flush Bottom Control Valves, including manual, actuated, and Y-type flush bottom valves. Manual valves are operated by hand, while actuated flush bottom valves are controlled remotely through pneumatic or electric actuators. Y-type flush bottom valves are specifically designed for applications requiring high flow rates or the handling of viscous fluids.

Applications of Flush Bottom Control Valve

Flush Bottom Control Valves find applications in industries such as pharmaceuticals, food and beverage, chemical processing, and wastewater treatment. They are used in processes requiring frequent cleaning, such as batch mixing, reactor vessels, and storage tanks. These valves ensure thorough drainage, minimize product loss, and maintain hygienic conditions.

Why Choose FRETURE Flush Bottom Valves?

FRETURE Flush Bottom Valves are engineered with precision and manufactured using high-quality materials, ensuring durability and reliability. Our valves are designed for easy maintenance, with minimal downtime and reduced operational costs. Whether you need a manual, actuated, or Y-type flush bottom valve, we provide customized solutions to meet your specific requirements. As a trusted flush bottom valve supplier, we prioritize customer satisfaction and offer exceptional after-sales support.

Description | Features |

|---|---|

Type : Disk Opening into the Tank | Disk Opening into the Pipe End Connection : Flanged RF / FF Size : 15NB - 450NB Class : 150# - 1500# Body Materials : Carbon Steel, S.S.304, S.S.316, S.S.304L, S.S.316L, Alloy 20, Hastelloy & As per Special Specifications Design Standard : BS 5351 / ANSI B 16.34 / API 6D Trim Design : Skirt Guided, Linear, Pressure Balance Face-to-Face : ISA S.75.03 up to 600# Plug : Large Seat Area, Open Inside Vessel or Inside Valve Body Actuator Type : Diaphragm, Piston, or Electric Actuator Action : Direct / Reverse Acting Handwheel : Top or Side Mounted Handwheel Accessories : Airset, Solenoid Valve, Air Lock, Volume Booster, limit-proximity switches etc. |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How does a Flush Bottom Valve work?

- Are Flush Bottom Valves safe?

Yes, Flush Bottom Valves are designed with safety features to ensure reliable operation and prevent leaks or spills during draining or operation.

- What are the benefits of using these Valves?

Benefits include complete drainage of vessels, easy cleaning and maintenance, reduced risk of contamination, and compatibility with high-pressure and high-temperature applications.

- Can it handle high pressures and temperatures?

Yes, They are designed to handle high pressures and temperatures commonly found in industrial processes.

- Can Flush Bottom be used for both on-off and throttling applications?

Yes, they can be used for both on-off and throttling applications, providing precise control over fluid flow rates.

- How do I maintain a it?

Regular maintenance includes inspection, cleaning, and lubrication of the valve components to ensure proper functioning and longevity.

- Is it repairable?

Yes, most Flush Bottom Valves are designed to be repairable, allowing for easy replacement of worn or damaged components.

- Do I really need a Flush Bottom Valve for my factory?

If your factory requires frequent draining or cleaning of vessels, especially in industries like pharmaceuticals or food processing, a Flush Bottom Valve can improve efficiency and safety.

- How do I know which type of Flush Bottom Valve is ideal for me?

Consult with a valve manufacturer or engineer to determine the ideal type based on factors such as vessel size, fluid type, pressure, temperature, and control requirements.

- Why is Freture the best place to buy it from?

Freture is the best choice because of our precision engineering, high-quality materials, customization options, competitive pricing, comprehensive support, and commitment to customer satisfaction.

Industries where Flush Bottom Control Valve is used

Chemical Processing

Pharmacutical Industry

Food and Beverage Industry

Petrochemical Industry

Oil and Gas industry

Applications of Flush Bottom Control Valve

- Petrochemical: chemical reactors and process vessels.

- Pharma-Process: Pharmaceutical and biotechnology processes.

- Food and beverage: contamination-free transfer.

- Bio-Chem Industries: Abrasive and corrosive fluid handling.

- Refinary: hazardous and toxic fluid containment.