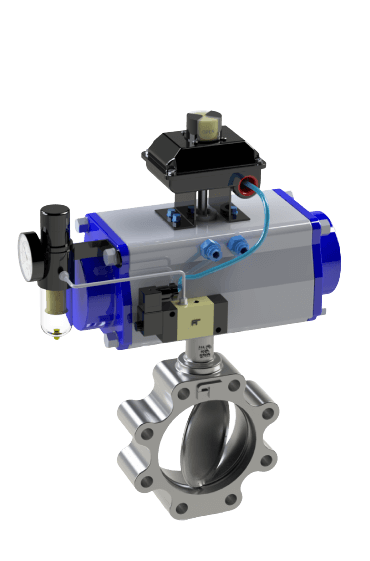

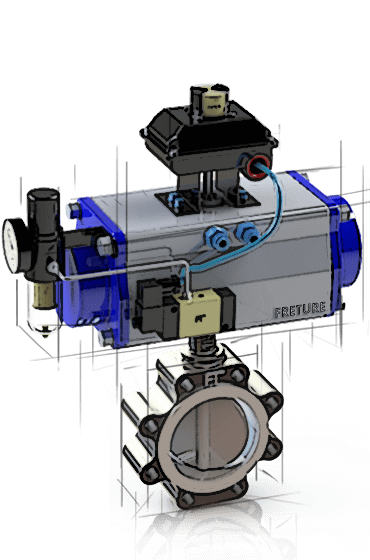

The valve operates by rotating a disc 90 degrees to control the flow of fluid. The double offset design allows the disc to move away from the seat with a cam-like action, providing a tight seal.

Double Offset Butterfly Valve

Reliable, Efficient, and Leak-Free Fluid Control

We are leading Double Offset Butterfly Valve Manufacturer in Mumbai, India. The first offset is the shaft, which is not at the centre of the disc but slightly behind it. Because of this misalignment, the valve will have a continuous sealing surface on the disc.

The second offset is the shaft, which is not in the centre of the pipe but slightly to the right of it. When the valve is fully opened, this offset ensures that it does not come into contact with the seat (see illustration above). This configuration causes less friction in the seat than the concentric type butterfly valve, extending its life. In a typical application, this Butterfly valve is only available in class 600.

A Reliable Solution for Precise Flow Control

The Valve is an advanced valve design known for its reliability, durability, and exceptional performance in controlling fluid flow. It features two offsets – the first being the offset of the stem from the centerline of the disc, and the second being the offset of the seat, creating a camming effect. This unique design ensures reduced seat wear and minimizes leakage, making it ideal for applications requiring precise flow control. This makes the these Butterfly Valve an excellent choice for industries looking for high-performance, leak-tight solutions.

High-Quality Materials

Constructed with high-quality materials such as stainless steel, cast iron, and aluminum bronze, It is suitable for a wide range of industries, including water treatment, oil and gas, chemical processing, and HVAC systems. Its robust material composition ensures longevity and resilience even in demanding environments, providing dependable service across various industrial applications.

Energy-Efficient and Easy to Maintain Design

This valve excels in both throttling and on/off applications, offering high sealing performance under varying pressure conditions. The design minimizes flow resistance, contributing to energy efficiency. The valve's versatility is enhanced by a range of actuators, including electric, pneumatic, and manual, providing flexibility for automated or manual operation. The compact design of the valve also allows for easy installation and minimal maintenance, making it a cost-effective solution.

Why Choose Freture Techno

For reliable and efficient fluid control, the Double Offset Butterfly Valve is a superior choice, ensuring long-term performance with minimal maintenance requirements. Whether used in water treatment, chemical processing, or industrial applications, this valve provides optimal performance and longevity.

Specifications | Features |

|---|---|

End Connection: Flange (B16.5) / Lug Type / Wafer Type Size: 15 NB - 600 NB Class: 150# - 600# Temperature Range: -190° C to 350 ° C MOC: Carbon Steel / Stainless Steel / Alloy Design Standard: EN 593 (BS 5155), API 609, MSS SP-67 Seat: Soft Seat ( Nitrile Rubber, EPDM ), Viton / Metal Seat Face to Face: API 609 CAT A / MSS SP-67 (Narrow Body), ISO 5752 (Short) Operation: Manual / Actuator / Gear Safety : BS/EN 10204-3.1 REV 2019, API 607, API 598 Rev 2009 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

- How does it work?

- What are the main applications?

Main applications include water and wastewater treatment, HVAC systems, chemical processing, oil and gas, and power generation industries where precise flow control and tight shut-off are required.

- What are the benefits of using one?

The benefits of using a Concentric Double Offset Butterfly Valve include:

- Excellent Sealing Performance: Provides tight shut-off capabilities, minimizing leakage.

- Reduced Friction and Wear: Streamlined flow path reduces friction and wear, extending the valve's service life.

- Precise Flow Control: Offers accurate and reliable flow control in various industrial applications.

- Versatility: Suitable for a wide range of fluids, including water, steam, gas, and corrosive chemicals.

- Compact Design: Space-saving design allows for easy installation and integration into existing piping systems.

- What materials are used in their construction?

Concentric Double Offset Butterfly Valves are commonly constructed from materials such as stainless steel, carbon steel, ductile iron, and various alloys. Sealing materials include EPDM, NBR, Viton, and PTFE, depending on the application requirements.

- How do I choose the right one for my application?

Choose based on factors such as the type of fluid, pressure rating, temperature range, valve size, end connections, and compatibility with specific application requirements to ensure optimal performance.

- Can they be repaired?

Yes, Concentric Double Offset Butterfly Valves can be repaired. Common repairs may include replacing seals, bearings, or other components to restore the valve's functionality.

- What maintenance is required?

Regular maintenance includes inspection, cleaning, and lubrication of moving parts to ensure smooth operation and prevent corrosion or damage.

- Are they available in different designs?

Yes, Concentric Double Offset Butterfly Valves are available in various designs, including different sizes, end connections, and actuation methods to meet diverse application needs.

- Why is Freture the best place to buy from?

Freture is the preferred choice for purchasing Concentric Double Offset Butterfly Valves due to our commitment to quality, extensive industry experience, and dedication to customer satisfaction. Our valves are reliable, competitively priced, and tailored to meet the specific needs of your applications.

Industries where Double Offset Butterfly Valves is Used

Wastewater Treatment

HVAC Industry

Chemical Processing

Oil and Gas Industry

Power Generation

Applications of Double Offset Butterfly Valve

- Flow Control: Precise control of fluid flow in various industries.

- Isolation: Reliable shutoff in critical applications.

- High-Temperature Services: Handling extreme temperature fluids or environments.

- Abrasive Media Handling: Suitable for handling abrasive materials.

- Emergency Shutdown Systems: Integrated for rapid and effective isolation during emergencies.