A ball valve is a type of quarter-turn valve that uses a hollow, perforated, and pivoting ball to control the flow of liquids or gases through a pipeline. The valve is operated by turning the handle or lever 90 degrees to open or close the flow path.

Floating Ball Valve Manufacturer in Mumbai, India

Ball Valves: Precision in Flow Control

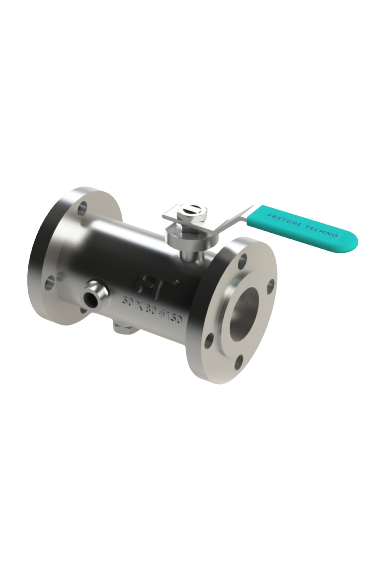

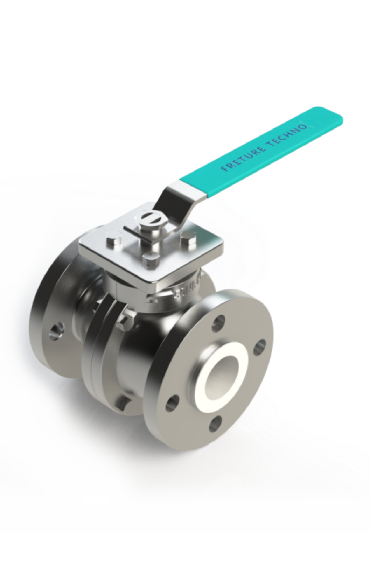

Freture Techno, a renowned Floating Ball Valve manufacturer in Mumbai, India, brings you a range of cutting-edge solutions for fluid control. Our Floating Ball Valves stand as a testament to precision engineering, ensuring reliable performance in various industries and applications.

Floating Ball Valve: Engineered Excellence

Key Features:

- Optimized Design: Our Floating Ball Valves are meticulously designed to provide smooth, low-torque operation, reducing wear and enhancing longevity.

- Seal Reliability: The floating ball design ensures a secure and reliable seal, minimizing leakage risks even under high-pressure conditions.

- Material Versatility: Available in a variety of materials, including stainless steel, carbon steel, and alloy options, to match your specific fluid compatibility and corrosion resistance needs.

- Size Range: From small-scale applications to heavy-duty industrial needs, our Floating Ball Valves are available in various sizes to meet diverse requirements.

- End Connections: Choose from a range of end connections, including threaded, flanged, and socket weld, for seamless integration into your pipeline system.

- Industry Compliance: Our Floating Ball Valves adhere to international standards and certifications, ensuring quality, safety, and performance excellence.

Why Choose Freture Techno for Floating Ball Valves?

With Freture Techno, you gain:

- Engineering Expertise: Benefit from our extensive knowledge and experience in fluid control solutions.

- Custom Solutions: We tailor Floating Ball Valves to your specific needs, ensuring a perfect fit for your applications.

- Global Reach: As a trusted manufacturer, we serve clients not only locally but also worldwide. Quality Assurance: Our Floating Ball Valves undergo rigorous testing, guaranteeing unmatched reliability.

- Competitive Pricing: Enjoy cost-effective solutions without compromising on quality. Make Freture Techno your partner for Floating Ball Valves, and experience precision, reliability, and excellence in fluid control. Contact us today to explore how our Floating Ball Valves can elevate your operations.

Description |

Features |

|---|---|

|

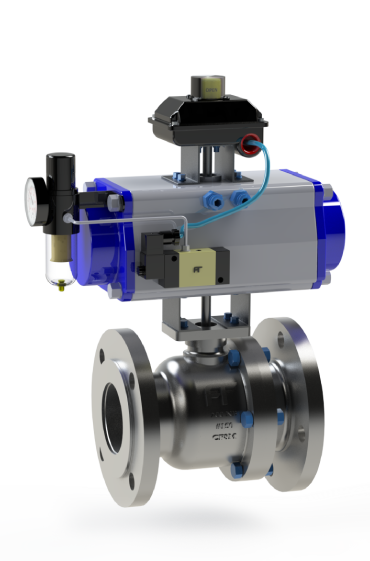

TYPE: One Piece / Two Piece / Three Piece Size: 15 NB - 300 NB End Connection: Flange / Butt Weld Pressure Rating: #150 - #600 Temperature Range: -7Deg C to 280 Deg C Body Materials: Stainless Steel / Carbon Steel / Alloys Design Standard: API 6D rev 23; ISO 17292 rev 2004 End Connection Std.: ASME B16.5 / B16.11 / B16.25 / ANSI 1.20.1 Face to Face: ASME B16.10 Rev 2009 Fire safe design: API-607 Rev 2010 Testing: API 598 Rev 2009 Sour Service: NACE MOR 0175 Rev 2009 Documents: BS/EN 10204-3.1 REV 2004 |

|

FAQ’s

Have a question before you buy our products? Take a look at the FAQs below.

If you don’t find the answer you’re looking for, get in touch with us here.

-

What is a Ball Valve?

-

What are the Advantages of Using Ball Valves?

Ball valves are known for their fast and reliable shutoff capabilities, minimal pressure drop, ease of operation, and suitability for a wide range of applications. They offer tight sealing and durability.

-

What Types of Ball Valves are Available?

There are several types of ball valves, including two-way (shut-off), three-way (diverter), and multi-port valves. They can be categorized as full-port or reduced-port, based on the size of the ball opening.

-

Can Ball Valves Be Used for Both On/Off and Flow Control?

Yes, ball valves are suitable for both on/off and flow control applications. They provide precise control when needed and complete shutoff when fully closed.

-

What Are the Common Materials Used for Ball Valves?

Ball valves can be made from various materials, including brass, stainless steel, carbon steel, and PVC, among others. The choice of material depends on the application's requirements.

-

Are Ball Valves Suitable for High-Pressure Applications?

Ball valves are often used in high-pressure applications due to their robust construction and tight sealing. However, the pressure rating varies depending on the valve's design and material.

-

Can Ball Valves Handle Corrosive Media?

Yes, ball valves can be lined or made from corrosion-resistant materials such as PTFE, PVC, or stainless steel to handle corrosive fluids.

-

How Do I Maintain a Ball Valve?

Maintenance typically involves periodic inspection for leaks and proper operation. Lubrication of the stem and seals may be necessary for some designs.

-

Can Ball Valves Be Automated?

Yes, ball valves can be automated using electric or pneumatic actuators for remote control and integration into automated systems.

-

Are Ball Valves safe?

Ball Valves are one of the safest and most efficient valves available. The fact that highly sensitive industries like oil and gas and chemical manufacturing companies use it extensively is proof that it is 100% safe and reliable.

-

Do I really need a Ball Valve for my factory?

If you are in one of the following industries, a Ball Valve will definitely help you improve the efficiency and safety.

- Chemical Manufacturing

- Oil & Gas Refineries

- Boiler / Reactor Manufacturing

- EPC Contractor company

- Local Traders

If you’re from another industry looking for more details about how you can benefit from using a Ball Valve, please get in touch with us here for further discussion.;

-

How do I know which type of Ball Valve is ideal for me?

Get in touch with us here and an expert from Freture Techno will help you decide.

-

Why is Freture the best place to buy Ball Valves from?

Most of the time our clients are local hence we are easily accessible

Our products are manufactured & Tested as per international Std. & we offered only best quality product

We will keep stock of Std. Product for last minute urgency

We provide products only from reputed & highly reliable manufactured

We have an experienced technical team who will be able to understand client’s exact requirements & accordingly we will offer solutions.

Industries where Ball Valve is Used

Chemical Manufacturing

Oil & Gas Refineries

Boiler / Reactor Manufacturing

EPC Contractor company

Local Traders

Applications of Ball Valve

- Boilers, ships, etc where this product is used

- Air, gaseous, and liquid applications requiring bubble-tight service.

- Low-point drains and high point vents in liquid, gaseous, and other fluid services.

- Cooling water and feed water systems.

- Steam service.